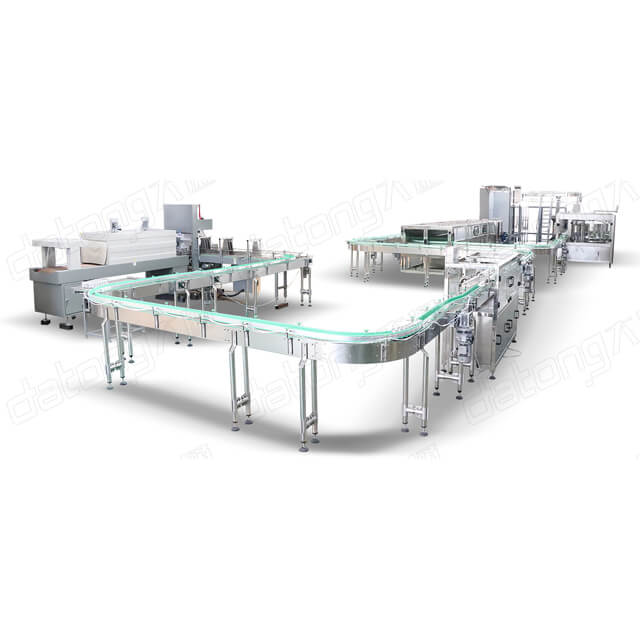

aluminum can filling machine

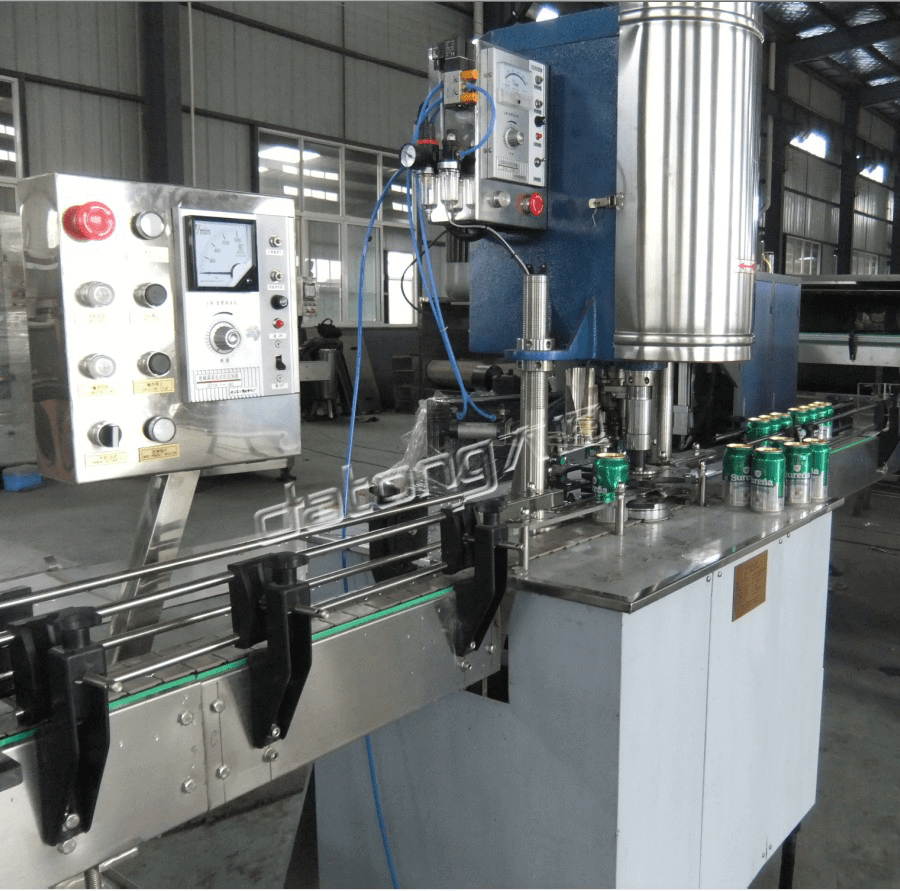

The machine is a device developed exclusively by DATONG MACHINE on the basis of digesting and absorbing domestic and international (still) pop can filling and seaming machines (sealing machines) . It adopts the normal pressure filling principle . After it passes through the dialing wheel , the empty can will enter into the lift can supporting disc , and the filling valve is aligned with the empty can , which will rise for sealing . Meanwhile , the valve port of the filling valve is automatically opened . When the filling liquid level blocks the gas return pipe mouth , the filling stops . The filled can will be conveyed to the sealing machine head by the hook chain . The cap will be sent onto the can mouth by the cap rises , the pressing head presses the can mouth , the sealing wheel carries out pre-sealing and then real sealing . After it is sealed , the can is pushed out by the beating head of the cap beating mechanism and then enters into the can discharging procedure .

The main electric components include PLC , frequency converter and proximity switch of Japan Mitsubishi , analog output module of Germany Siemens and solenoid valve of south korea , all of which are designed into the most reasonable configuration by our experienced electric engineers . The overall production speed can be set freely on the touch screen according to requirements . All common malfunctions will send out alarms automatically and malfunction causes and positions will be given correspondingly . According to different malfunction levels , the PLC will automatically determine if the operation shall continue or the machine shall be stopped .

The machine has such prominent features as high filling speed , consistent height from the liquid level in the can to the can mouth after filling , stable machine operation , good sealing quality , beautiful and decent appearance , convenient use and maintenance , etc .

| main technical parameters |

| Model | YGF12-4 | YGF18-4 | YGF20-4 | YGF30-6 |

| Production capacity | 5000CPH | 8000CPH | 12000CPH | 18000CPH |

| Can diameter | Φ52.5-99mm |

| Can height | 39-160mm |

| Power | 3.5kw | 5.5kw | 6.75kw | 7.5kw |

| Weight | 2500kg | 3500kg | 4000kg | 5000kg |

| Dimension | 2100*1500*1900mm | 2450*1750*2200mm | 2650*2200*2200mm | 3050*2250*2200mm |