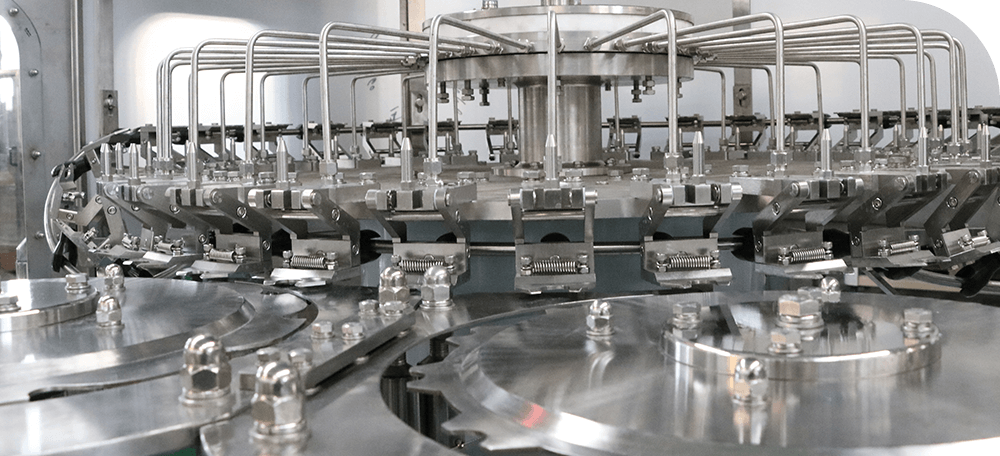

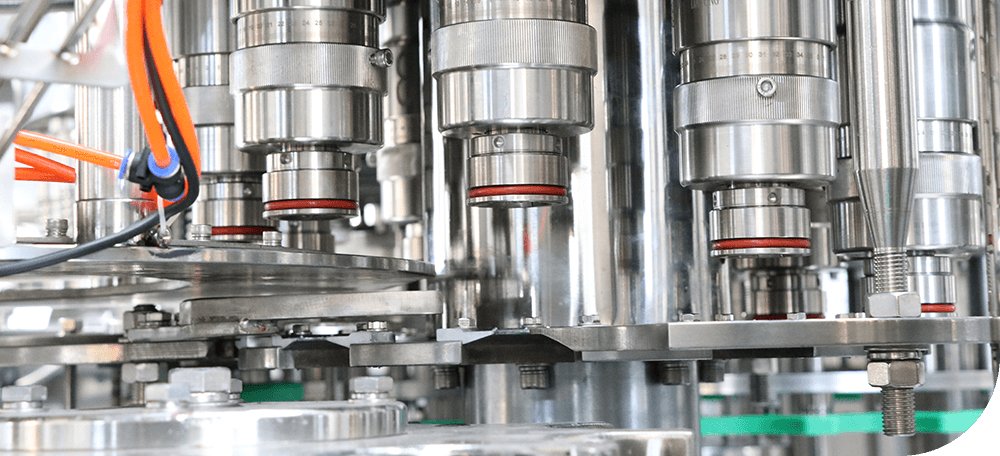

Capping Part

The capper is most precise part in 3 in 1 filling machine, because the quality of machine is important to running credibility and product quality. The sealing machine in our company has strongpoint as follows:

The cover track has the device to prevent the reversal cover from passing and pick out the reversal cover. Meanwhile the photoelectric switch can stop the machine automatically when there is no cover on the track, by which it can avoid bottle without cover effectively.

It also has the bottle check-up switch. Together with cylinder on the joint of the cover track and cover lift, they can control the cover flow and stop it in case no bottle to reduce the quantity of cover.

Highly effective acentric way for cap sorting to reduce the abrasion.

It has the check-up device to control the cover lift.