Product Features

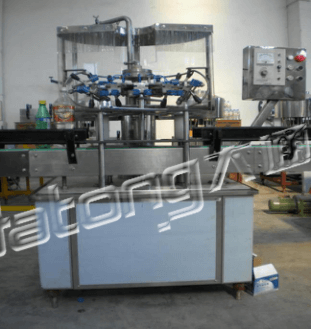

3 in 1 water filling machine offering various capacity from 2000BPH to 36000BPH

Different shapes of PET bottle filler machine like circular or square

Various size such as 5 gallon or 5-10L bottle or 200-2000ml Bottle

Food grade SU304 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

Advanced human-machine interface control

High quality international name brand key electrical components such as Japan's Mitsubishi, France Schneider, OMRON

High-speed large gravity filter

Low overall machine noise

High efficient air clean filter system

apply to the production of non-carbonated drinks as pure water, mineral water, distilled water, spring water and other bottled water

Built-in safeguard mechanism ensures the safety of operator and machine.

Spring type rinsing catcher can wash both inside and outside of the bottle

3-in-1 monoblock including washing,filling and capping

If your water plant needs custom bottled water filling machine, please contact us to do one-on-one communication, we can surely give you the best experience and price.

Three Types of Water Filters

Datong Machinery offers three types types of drinking water filtration systems, so you can make an educated choice about which one is the best for your production line.

Atmospheric pressure Fillers

Atmospheric pressure filling, is filling under atmospheric pressure by the self-weight of the liquid, also known as gravity filling. This type of filling machine is also divided into two kinds of timing filling and constant volume filling, which is only suitable for filling low viscosity liquid without gas, such as drinking water, milk, liquor, mineral water, etc.

Pressure Fillers

It is filling under higher than atmospheric pressure, which can also be divided into two kinds: one is that the pressure in the storage cylinder is equal to the pressure in the bottle, and the liquid flows into the bottle by its own weight and filling, called equal pressure filling; the other is that the pressure in the storage cylinder is higher than the pressure in the bottle, and the liquid flows into the bottle by the pressure difference, which is mostly used in high-speed production lines. Pressure filling machine is suitable for filling liquid containing gas, such as beer, soft drink, champagne, etc.

Vacuum Fillers

This type of filling machine has a simple structure, high efficiency, and a wide range of material viscosity adaptations, such as oils, syrups, and fruit wines.

Automatic & Semi-automatic Filling Machines

According to the type of filling operation, it can be divided into automatic & semi-automatic liquid filling machine.

Automatic liquid filling machine is improved design on the basis of filling machine series products and added some additional functions. It makes the filling machine easier and more convenient in terms of using operation, precision error, loading adjustment, equipment cleaning and maintenance.

Semi-automatic liquid filling machine is liquid single head automatic filling machine, also known as semi-automatic piston filling machine, for filling volume and filling speed can be adjusted at will, is a very practical small liquid quantitative filling machine.

Advantages of Automatic Water Bottle Machine

Datong Machinery offers a wide range of drinking water canning line solutions that are able to meet the needs of different bottle shapes such as glass bottles, PET bottles, aluminum cans, etc. And we offer automatic water bottle filling machines with many benefits.

Save labor: The advantage of automatic filling machine is that it does not require manual operation to complete production, realizing automatic filling, automatic bottle management, bottle conveying, automatic capping and other operations.

Cost reduction: Automatic filling machine eliminates the manual steps and reduces the cost caused by manpower. Moreover, the automated product is highly efficient and only needs to adjust the equipment according to the product type, and it can be canned directly.

Convenient maintenance: automatic filling machines are easy to maintain, the equipment is controlled by computer programs, and can be operated and maintained with proper training, which can save a lot of time and reduce the trouble caused.

Why choose Datong Machinery

Datong is a professional liquid filling & packaging machine manufacturer in China, and we serve a lot of drinking water packaging plants around the world. Our equipment is the introduction of the production technology and process of American companies. It has advanced technology, reliable performance and process flow. Scientific, good food hygiene conditions, high production automation, and easy operation. It is a piece of ideal water filling equipment for beverage manufacturers and is well received by the food and beverage industry.