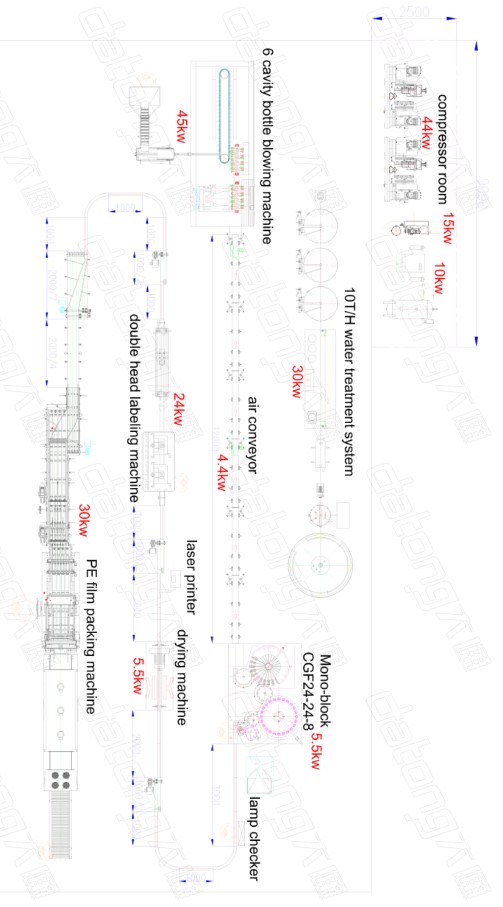

| water treatment system

1 Raw water tank + Raw water pump 2 Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter 3 Reverse Osmosis (one level) 4 UV sterilizer 5 Finished water tank + Pure water pump

1.Stainless steel high pressure film shell 2.All kinds of capacity indicator, pressure indicator, electricity magnetic valve, balance device and pipe valve system 3.Online type pressure auto self-protection device 4.Online type electricity indicator (with stable compensation) 5.System safe protecting and alarm system 6.System frame |

|

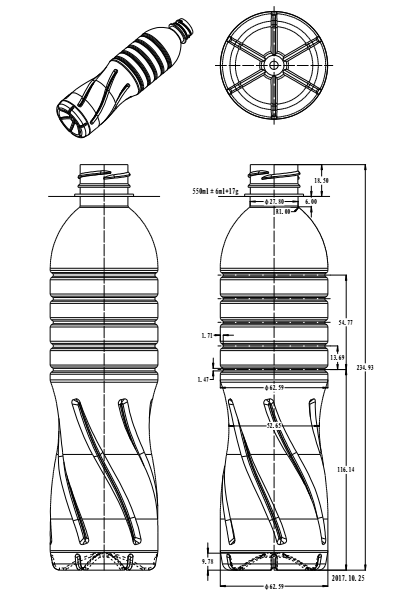

PET bottle blowing machine Full automatic blow molding machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

|

|

water filling washing and capping machine

By 3-in-1 monoblock ,the bottle goes through washing,filling and capping with little abrasion,and the transferring is stable,bottle changing is easier. Specially designed stainless steel bottle gripper dose not contact the thread parts of the bottle neck,avoiding the second contamination. High speed and mass flow filling valve ensures the high filling speed and exact fluid level.

|

washing part

The rotary wheel is a fully SUS304 stainless steel welded structure.

The machine applies unique overturning bottle clamp, which is an innovation of our company. This bottle clamp grips bottle at neck position, avoiding bottle mouth thread contamination caused by rubber gripper block of a traditional bottle clamp. Made of SS304 stainless steel, this bottle clamp is hygienic and durable.

The high efficiency atomizing spray nozzle installed on bottle clamp incorporating technology from Spaying Systems Co. Ltd., is capable of cleaning any part of bottle inner wall, and also saves rinsing water.

The rinse is driven by driving system positioned inside machine frame via gear transmission.

filling part

The filler is designed and manufactured with application of Italy technology, providing hardware guarantee for securing product quality and reducing loss.

Rotary wheel are fully made of stainless steel SS304.

Filling valves are designed and manufactured with German technology, made of SS304, featuring high filling accuracy and high filling speed.

Bottles are raised and lowered by cam controlled lifting cylinder. Valve opening mechanism is actuated by air cylinder.

Hydraulic pump is float-ball controlled.

The filler is driven by driving system positioned inside machine frame via gear transmission.

capping part

The capper is most precise part in 3 in 1 filling machine, because the quality of machine is important to running credibility and product quality. The sealing machine in our company has strongpoint as follows:

The cover track has the device to prevent the reversal cover from passing and pick out the reversal cover. Meanwhile the photoelectric switch can stop the machine automatically when there is no cover on the track, by which it can avoid bottle without cover effectively.

It also has the bottle check-up switch. Together with cylinder on the joint of the cover track and cover lift, they can control the cover flow and stop it in case no bottle to reduce the quantity of cover.

Highly effective acentric way for cap sorting to reduce the abrasion.

It has the check-up device to control the cover lift.

|

Labeling machine

It adopts double driving structure which is a new and advanced driving device for the thermal shrink sleeve machine, that is,four-wheel driving, self-centering and balanced pressure of four wheels. It can achieve the good effect of transmission of labels smoothly, stably and rapidly.

|

Film shrinkable packing machine high speed filling shrinkable packing machine with high effect and Good shrinkage. |

|