Water bottle filling machine with capacity from 2000BPH to 36000BPH. This kind of packing features light, good-tenacity, strong-intensity and hard-breakage, in addition, PET bottle can be made into different specs and shapes; For the consumer, they can take easily and conveniently without exploding.

Features:

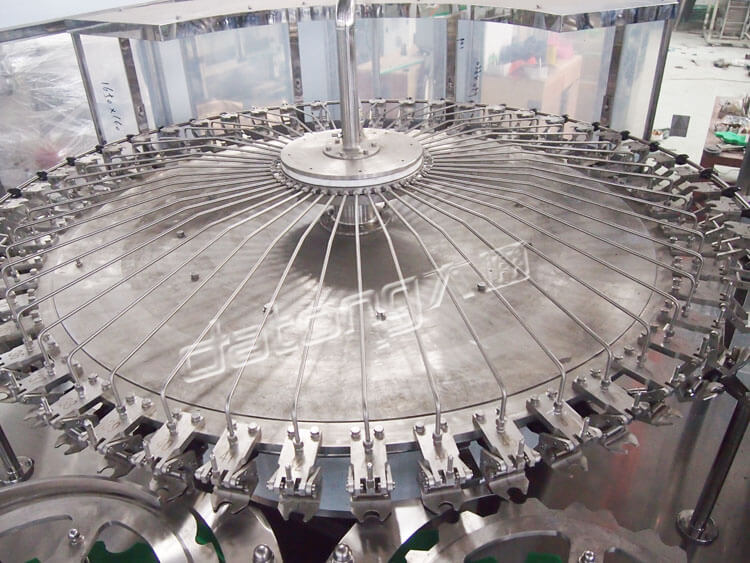

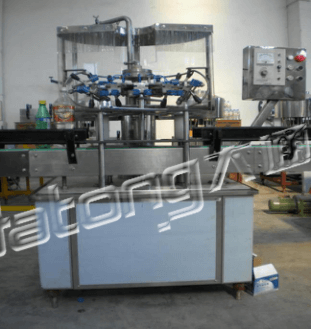

1. The mineral water filling machine adpots advanced human-machine interface control. High quality international name brand key components

2. Suspension bottle neck catcher structure allows the machine change the bottle type easily. By changing the valves, it also can be used as hot filling machine

3. Spring type rinsing catcher can wash both inside and outside of the bottle

4. High accuracy pressure water filling mechanism, ensure the height and quatity of the water filling

5. Magnetic powered cap device ensures tightness and prevents damage of the caps

6. Quiet, rotary cap unscrambler will not damage caps. Photoelectric sensor detect missing caps thus eliminating uncapped bottle spillage

7. Built-in safeguard mechanism ensures the safety of operator and machine.

8. High efficient air clean filter system ensures high sanitary requirements

9. Low overall machine noise

10. Self-lubricating system imported from America provides continuous smooth operation

Model |

CGF12125

|

CGF18186

|

CGF24248

|

CGF323210

|

CGF404012

|

CGF505012

|

CGF606015

|

CGF808020

|

Number of washing, filling and capping heads

|

12-12-5

|

18-18-6

|

24-24-8

|

32-32-10

|

40-40-12

|

50-50-12

|

60-60-15

|

80-80-20

|

Production capacity(600ml)

(B/H)

|

2000-4000

|

5000-7000

|

8000-12000

|

12000-15000

|

16000-20000

|

20000-24000

|

25000-30000

|

35000-40000

|

suitable bottle specification(mm)

|

φ=50-110 H=170 volume=330-2250ml

|

Washing pressure(kg/cm 2 )

|

2-3

|

Motor power(kw)

|

Main motor

2.2kw

|

Main motor

2.2kw

|

Main motor

3kw

|

Main motor

5.5kw

|

Main motor

7.5kw

|

Main motor

11kw

|

Main motor

15kw

|

Main motor

19kw

|

Overall dimensions (mm)

|

2400×1650

×2500

|

2600×1920

×2550

|

3100×2300

×2800

|

3800×2800

×2900

|

4600×2800

×2900

|

5450×3300

×2900

|

6500×4500

×2900

|

76800×66400

×2850

|

Weight (kg)

|

2500

|

3500

|

4500

|

6500

|

8500

|

9800

|

12800

|

150

|

Bottle Design Service

Our engineer can design different bottle drawing for your reference!

Contact Us: We will send design drawing!

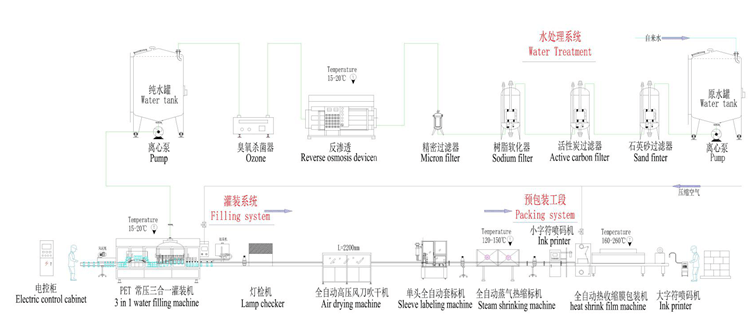

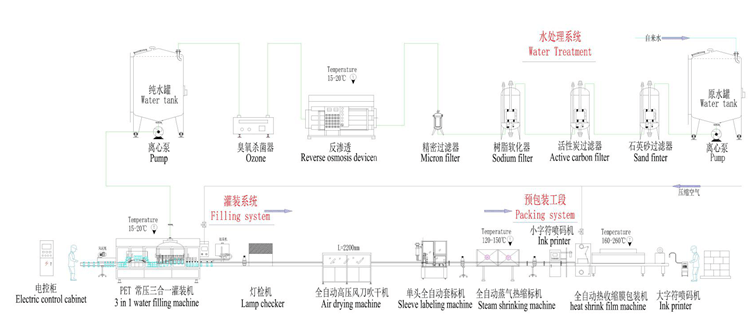

Layout Design Service

We supply standard layout for each water filling machine line,

also available for customize design layout based on Customers Factory Area!

Give US: Factory Area

Label Design Service

Design colorful label for customers choice

Provide Us: Information want to put on label

DATONG Sales Service

Before Sales

1.Answer your any question on us within 24 hours.

2.Supply all information you required.

3.Machines video for reference

4.Welcome to visit factory

On Sales

1.Update production progress each week

2.Sending machines pictures on production

3.Machines testing running over 8 hours, and sending testing videos

After Sales

1.engineer arranged to install machines

2.Spare Parts provided

3.After sales hotline: 0086-512-58662088