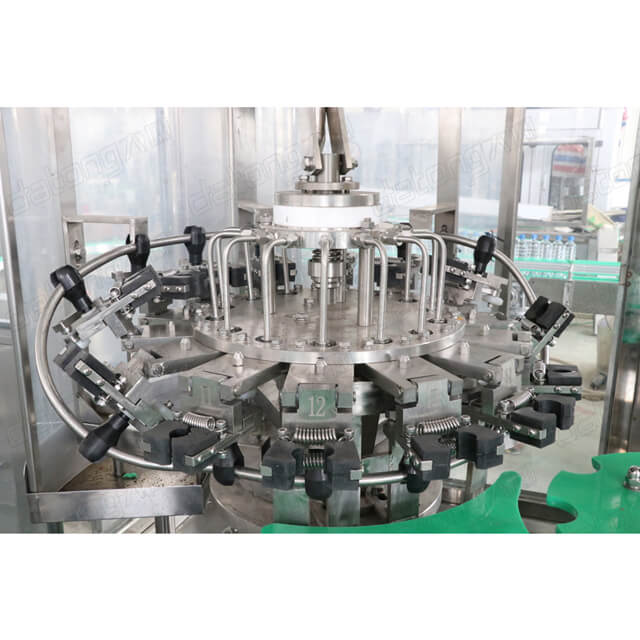

14-12-5 glass bottle mineral water filling machine

1. Adopt food grade SUS304 stainless steel material, compact structure, reasonable design, small footprint, production capacity from 2000-36000b/h all can be customized;

2. PLC control, touch screen human-computer interaction interface, easy to operate, easy to maintain; The whole line output can be adjusted and has good compatibility and expansibility.

3. Perfect to meet customer needs, has small investment, quick results! It is small and medium-sized bottled water manufacturers ideal production and processing equipment!

Glass bottle Water filling whole course video

By 3-in-1 monoblock, the bottle goes through washing, filling and capping with little abrasion, and the transferring is stable, bottle changing is easier. Specially designed stainless steel bottle gripper dose not contact the thread parts of the bottle neck, avoiding the second contamination. High speed and mass flow filling valve ensures the high filling speed and exact fluid level. parts contacting liquid are all made of excellent stainless steel or food grade engineering plastic. the electric system is from international brand and achieves the national food hygienic standard. the bottle-out starwheel is helical structure. while changing over bottle size. It is no need to adjust bottle-out conveyor height.

Model | CGF14-12-5 | CGF16-16-6 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 | CGF40-40-12 | CGF50-50-15 | CGF60-60-15 |

Production capacity(b/h)

| 2500 | 4000 | 6000 | 8000 | 13000 | 18000 | 22000 | 26000 |

Suitable bottle

shape | circular or square |

Bottle diameter(mm)

| Φ50-Φ95 |

Bottle height(mm)

| 150-310 |

Washing medium

| aseptic water |

Total power(kw) | 3 | 3.5 | 4 | 5.5 | 7.5 | 11 | 15 | 20 |

Weight(kg)

| 2200 | 2800 | 3000 | 4500 | 6000 | 9000 | 15000 | 18000 |

Overall dimensions(mm) | 2050*1550*2200 | 2400*1750*2200 | 2550*1850*2200 | 3000*2150*2200 | 4200*2700*2400 | 4700*3200*2400 | 6500*3350*2400 | 7200*3650*2600 |

The above technical parameters are subject to continual update,please take the real product as the base. machines can be customized for special products.

The overall structure integration

The 3-in-1 unit completed the three processes of washing bottle, filling and sealing.

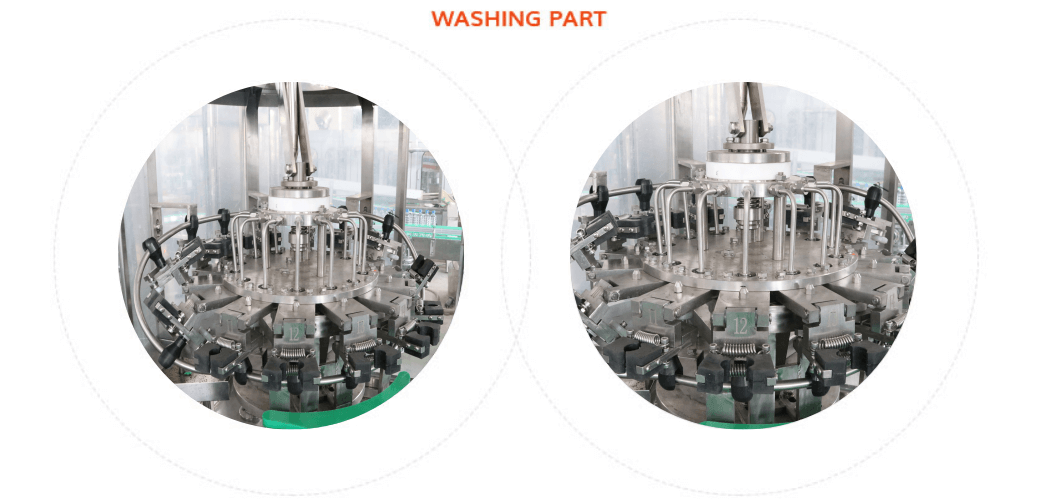

< Bottle washing clamp >

stainsteel tube, bottle washing clamp isometric design.

Specially designed stainless steel bottle gripper does not contact the thread parts of the bottle neck,avoiding the second contamination.

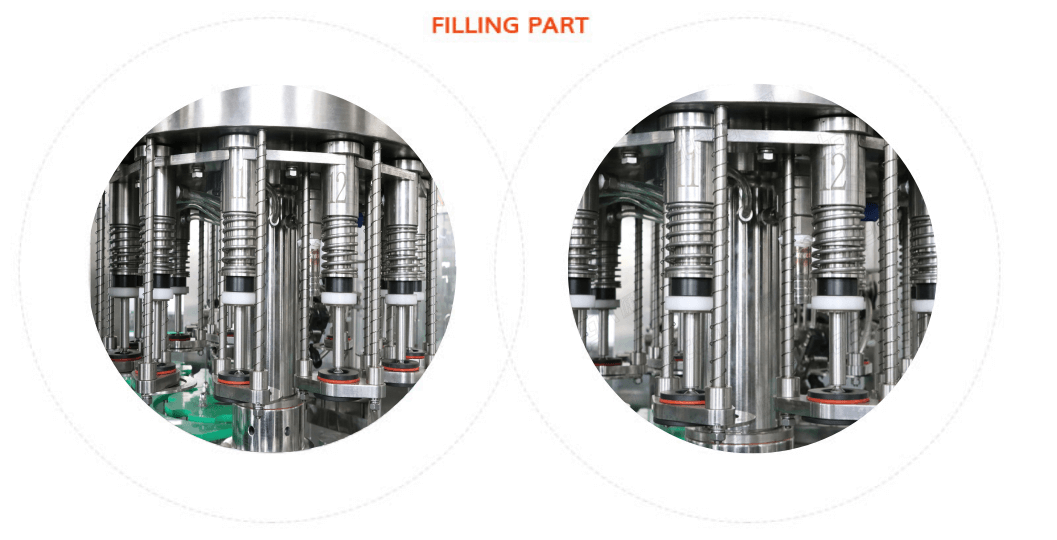

< Filling valve >

High speed and mass flow filling valve ensures the high filling speed and exact fluid level. Parts contacting liquid are all made of excellent stainless steel or food grade engineering plastic. filling valves, machine scutcheon etc. use laser printing.

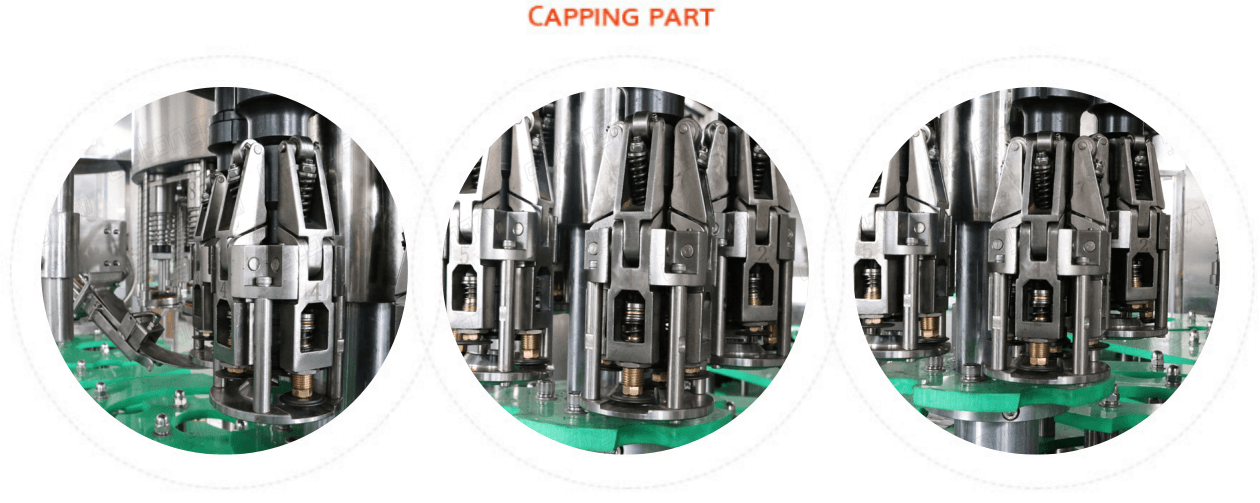

< Gland device >

capping head have itself scale. Easier adjust and count.

Customer installation scene and production field