- Home

-

Products

- Water treatment purification system

- Water Filling Machine

- Juice filling machine

- Carbonated drink filling machine

- Glass bottle filling machine

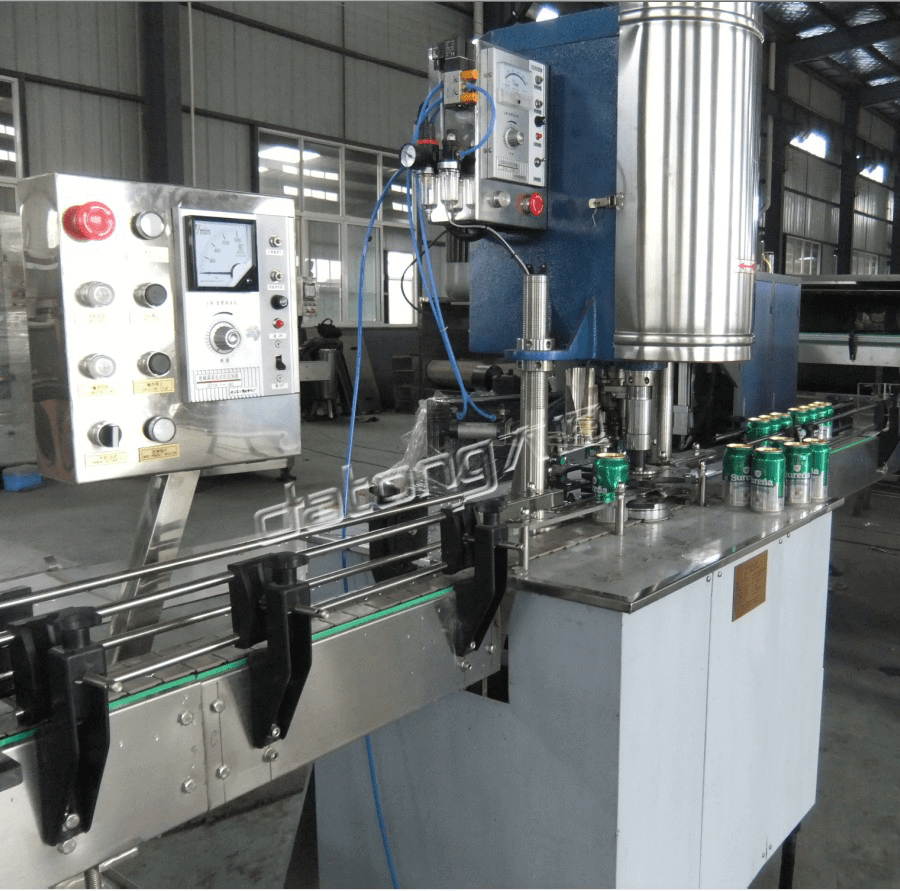

- Can filling machine

- 3-5 gallon barrel water filling machine

- 5-10L water filling machine

- Bottle blow molding machine

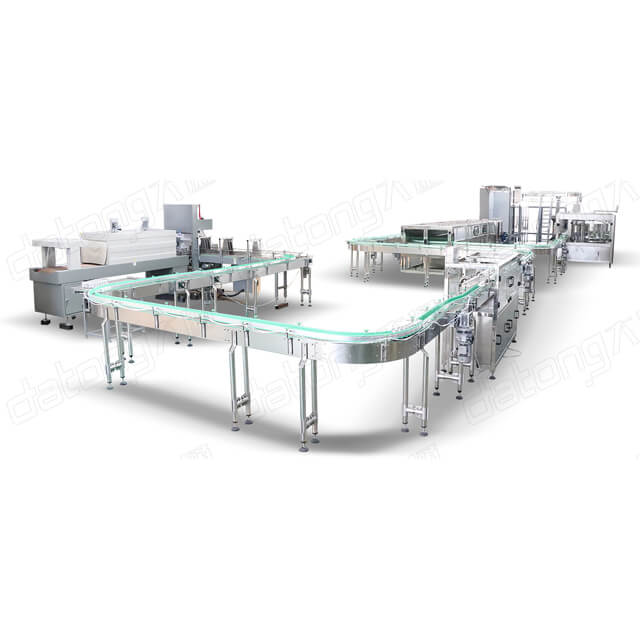

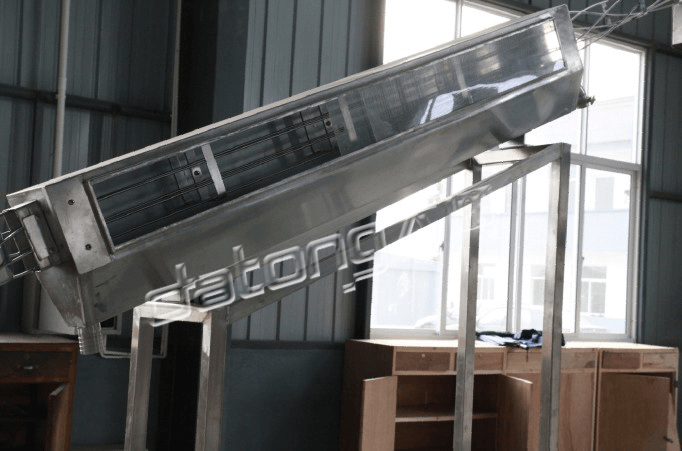

- Conveyor system

- Bottle labeling machine

- Automatic packaging machine

- Find By Liquid

- Solution

- Videos

- Service

- Company