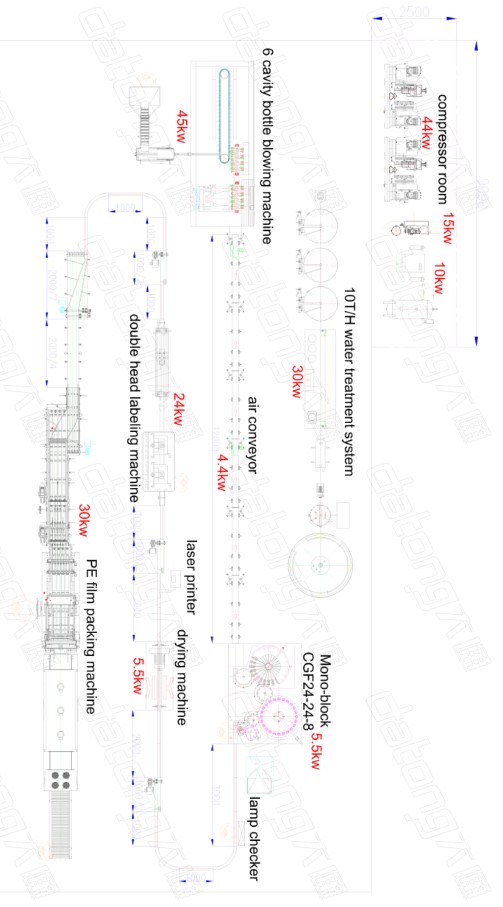

1. The water treatment system can be designed and produced according to the raw water quality report of customers or the standard requirements of World Health Organization for real-time living drinking water.

2. All valves and pipelines are made of SUS304 or SUS316L stainless steel with compact structure

3. The whole machine is controlled by PLC, which can be operated automatically, and equipped with conductivity meter

Gauges, pressure gauges and flowmeters. All parameters of the machine can be easily monitored.

4. After being treated with quartz sand, activated carbon, and sodium filter, the water is cleaner than before. But it is still not at its best. In the whole process, a major process is the reverse osmosis special membrane, in order to better protect the membrane in reverse osmosis, we must add precision filter, used to clean the final large volume of material in the water.

5. The water will be pumped into the reverse osmosis unit and about 70% of the raw water will become pure water and the rest will be wastewater, which will then be discharged into the water treatment system.

| STAINLESS SYEEL MULTISTAGE CENTRIFUGAL PUMP

Material is pump body stainless steel SUS304. Working condition:liquid with thick, clean, non-flammable,non-explosive,and doesn't contain solid particle or fiber. |

THE FILTER

Filter element is composed of quartz sand filter element, activated carbon filter element and sodium filter element. The raw water is pumped into the quartz sand filter with high pressure pump. Any particles over 20um will be filtered through the quartz sand in the filter, such as precipitate, manganese, rust, colloidal material, etc., as well as mechanical filtration of impurities and suspended solids.

Then the water goes through the activated carbon filter, which absorbs the odors and chemical residues in the water. The third step, sodium filtration, reduces the heavy metal content in the water, leading to more healthy drinking water. The filter is equipped with a backwash system. The user should connect the pump to each filter and open the relevant valve for backwash.

RO

The pore size of the membrane in the reverse osmosis device is 0.001 micron. After this process, 99.2% of the heavy metal ions and carcinogens in the water are absolutely removed.

All kinds of capacity indicator, pressure indicator, solenoid valve, balance device and pipeline valve system.

On-line pressure automatic self-protection device.

On-line electric quantity indicator (with stable compensation)

System safety protection and alarm system.

| OZONE GENERATOR

Ozone molecule As a kind of strong oxidizers with its function on the field of sterilizing. It has the special function to deal

with the poisonous and Hardly-decomposed contamination and to improve the biology activity.

|