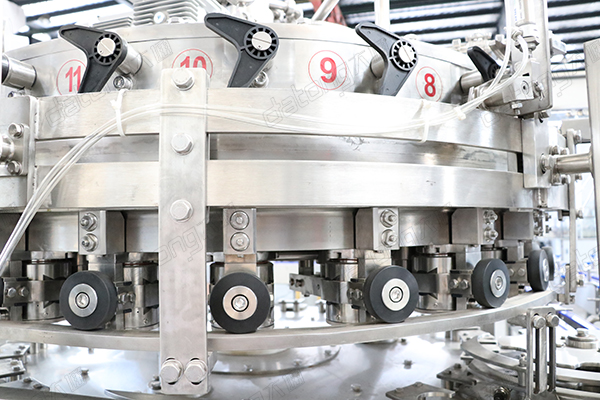

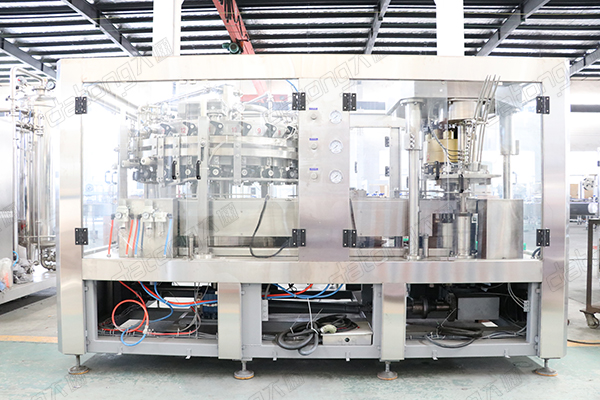

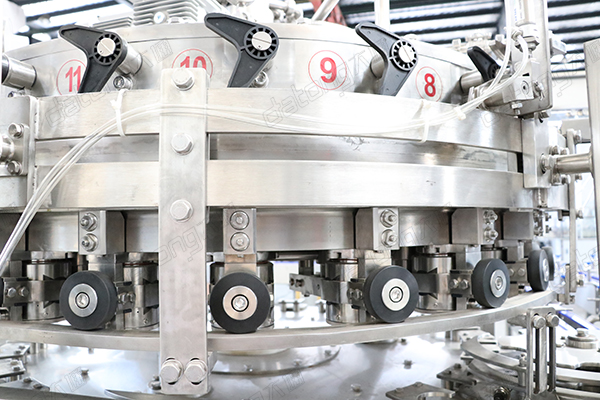

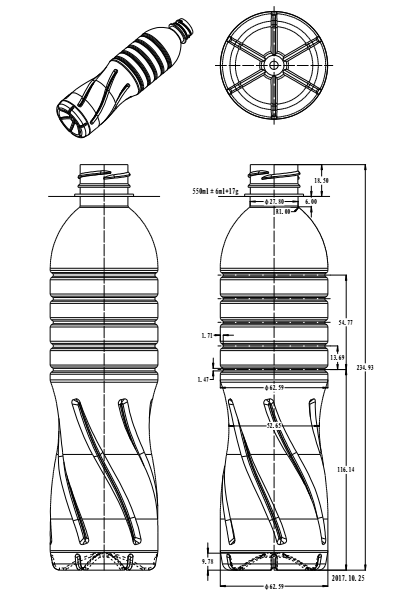

This equipment is used for filling carbonated beverage in cans , such as beer, cola, energy drinks and soda water.This equipment can be used for different material of cans, such as plastic, iron, aluminum and so on ,and the different size of cans is allowed.We can design the equipment according to your requirements

- Home

-

Products

- Water treatment purification system

- Water Filling Machine

- Juice filling machine

- Carbonated drink filling machine

- Glass bottle filling machine

- Can filling machine

- 3-5 gallon barrel water filling machine

- 5-10L water filling machine

- Bottle blow molding machine

- Conveyor system

- Bottle labeling machine

- Automatic packaging machine

- Find By Liquid

- Solution

- Videos

- Service

- Company