9.3 micron application scenario

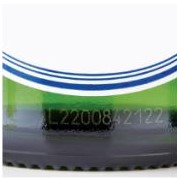

Typical coding needs:

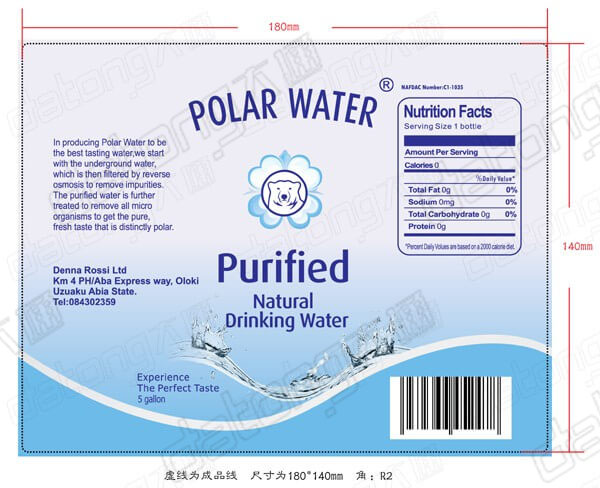

PET packaging manufacturers are increasingly turning to "thin-walled "PET in an attempt to reduce costs and waste. This makes it difficult for laser markers because thinner materials can burn through. This problem can be solved by selecting an appropriate wavelength to produce an alternative labeling effect. Another requirement for PET labeling is the ability to print at high speed, as most of these applications are using high speed alphanumeric expiration dates and lot information on beverages

Logo effect:

Foaming - Best labeling effect for "thin-walled" PET

Engraving - suitable for thicker PET materials

Mark speed:

typical speed 10,000-30,000 bottles/h

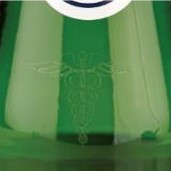

10.6 micron application scenario

Typical coding needs:

Laser marking systems typically print serial numbers, internal tracking numbers, and traceability information on glass (white or stained glass). QR codes are less common, but can be implemented by using the appropriate dot size. It is recommended that the glass be marked with a small dot size to achieve a smooth marking effect. Using larger spot sizes can cause large microcracks and is rough to the touch

Logo effect:

Etch microcracks/cracks on the glass surface

Mark speed:

It usually has a maximum speed of 80m/min or 60000 bottles/hour

Typical coding requirements:

Laser Coding Machine is suitable for printing on two main types of metal materials: coated metal and anodized aluminum. Typical applications typically require the printing of trade marks or alphanumeric characters, such as batch numbers. High quality DataMatrix codes can also be printed for identification on anodized aluminum. For coated metal, if the coating is too thick, it may cause inconvenience to laser printer. To achieve the desired marking effect, it may be necessary to increase the power of the laser printer or reduce the speed of the packaging line

logo effect:

Change color-anodized aluminum to remove color-coated metal surface

Mark speed:

Typical trademark (anodized)1-2 SEC. Typical Datamatrix code 0.5 SEC

Technical Data

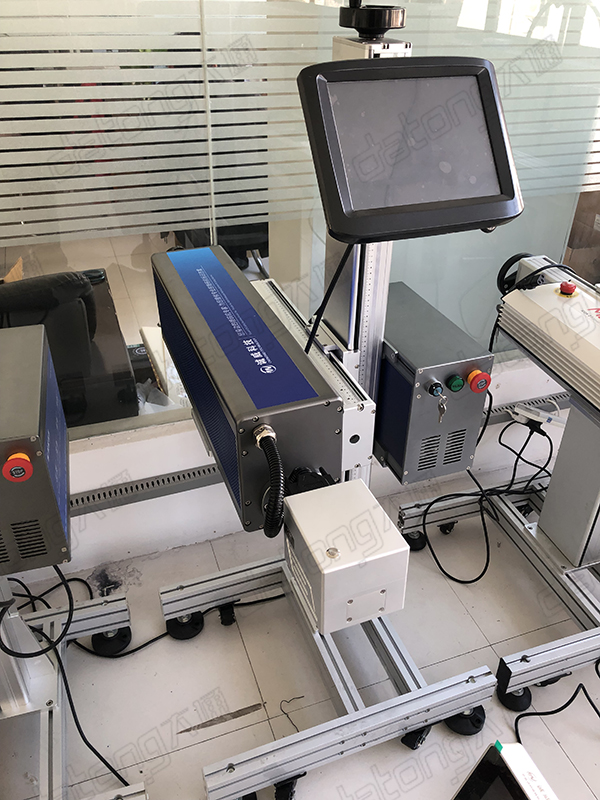

It is mainly composed of laser generator, deflection galvanometer, photoelectric sensor, main controller and power supply.

Chengwei C60XX series laser marking machine is the latest application of dynamic laser marking control system.The system is equipped with software and hardware functions to control the motion precision parameters, synchronously track the fast-moving workpiece and control the laser output, and mark when the production line moves rapidly and the workpiece nonstop. Markers are both dot and vector.It can run continuously 24 hours at the working site.

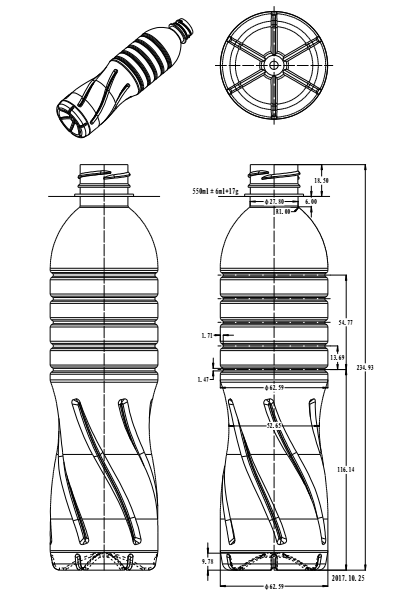

Technical Specifications:

Model Item | CO2 C6011 | CO2 C6030-F |

Laser Machine Characteristics | Material | All aluminum structure |

Laser | Sealed metal radio frequency carbon dioxide laser generator |

Continuous output power | ≥10W | ≥30W |

Laser wavelength | 9.3um | 10.6um |

Galvanometer deflection | High precision Double d scanning system |

Engraving speed | ≤7000mm/s |

Master control | Highly integrated motherboard with 10 inch screen |

Operating system | WIN CE |

Cooling System | Air cooling system |

Laser Parameters | Focus lens | Focal length 138 mm |

Marking type | Dot matrix and vector machine (can play both dot matrix and vector) |

Minimum line width | 0.03mm |

Repositioning Accuracy | 0.01mm |

Marking area | 110mm×110mm(Choosable) |

Locate mode | Red light focusing |

Lines to type | Any lines in the marking range |

Production Line Speed | 0~100m/min (depends on the material) , 0~200m/min (depends on the material) |

Support Types | Font | Standard Chinese and English, Numbers, etc |

File Format | BMP/DXF/HPGL/JPEG/PLT |

Bar codes | CODE39、CODE128、CODE126、QR、真知码 |

Parameters | Power | 220V |

Power Consumption | 300W | 650W |

Machine net weight | 14kg | 25kg |

· 3 d bracket net weight | 30kg |

Operational Reliability | External temperature 0℃-45℃;Humidity≤95% or less; Non - Condensing;No vibration |