1.Marked station is the heart of the aircraft, designed to complete the standard trademarks station transmission constant

2.The opp hot melt glue labeling machine host used on home cam design to replace the bottle-type simple ;nose tight card using pneumatic means to increasethe convenience of the host.

3.The overall automation and control the use of PLC control, the servo system ,the inverter system, temperature controlsystems and other needs with comprehensive control of the point.

4.Overload protection ,security ,protection of the design of complete, multi-point and fault protection device to ensure that the alarm sound and light man-machine safety.

5.Centralized lubrication system allows the operation of machinery lubrication components more simple, long life. The machine is simple and convenient maintenance.

6.A specially designed folder structure to ensure that trademarks are trademarks of trademarks has always been flexible in compacting the folder block.

7. Servo motor-driven traction trademark agencies, photoelectric color code detection and compensation structure of a trademark can be cut off to ensure that trademarks are timely, accurate,and neatly cut.

8.Biaxial screw propeller institutions bottle into the bottle so that a more stable,high-speed into the bottle so much more smoothly.

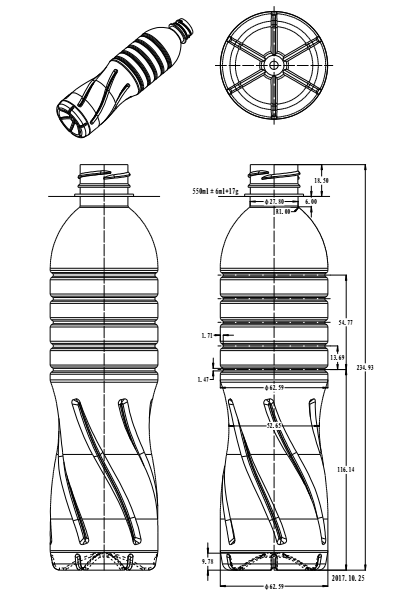

9.Inflatable bottle of the local function is the quality of the container(grams)low, allowing users to reduce operating costs.

10.Double disk structure to ensure that the user feed the least time to replace the membrance ,so that the effective production of longer,more productive machines.