Things to consider when you choose labeling machine

Views: 415

Author: Site Editor

Publish Time: 2021-06-01

Origin: Site

In most manufacturing industries, labeling is a crucial process for goods and finished products. Companies invest in hi-tech pressure-sensitive label applicators to streamline their labeling processes. It is hard to imagine specialty industries like the pharma industry, the food and beverage industry, and the cosmetic industry without proper labeling systems, isn't it?

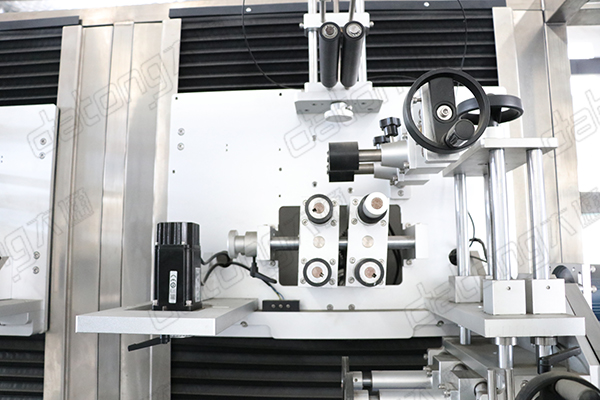

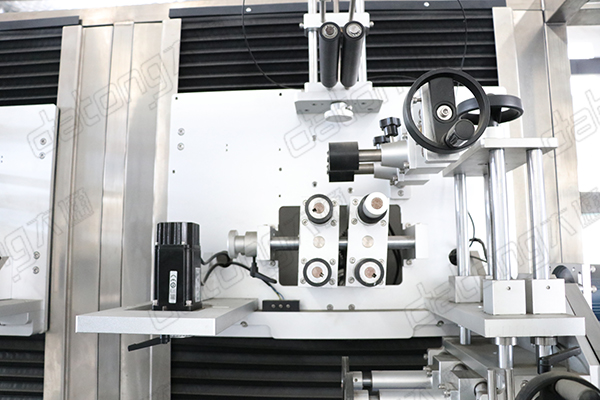

Specialized label applicators are used to apply pressure-sensitive labels onto bottles, product containers, drums, or packages. Label applicators can either apply pre-printed labels, or they can print information directly onto the labels and then apply them to products. Ideal label applicators enable seamless integration into your existing production systems. But, how do you determine which label applicator is best suited for your business?

To help you choose the right label applicator, here are few guidelines you can consider.

1. Product Surface

One of the key factors to consider while choosing a label applicator is the surface of the product. Typically, product surfaces can be concave, convex, or flat. Another thing to take into consideration is the kind of material on which the label is going to be applied. Product surfaces are usually made of plastic, metal, and paper. Whatever be the material of surface type, your label applicator should be compatible with it.

2. Label Materials

Label materials are commonly made of paper, foil, or film. Different label materials are used for different kinds of products. For example, white BOPP labels are impervious to water and oils and are used for bath and body products, along with food and beverage products. Clear BOPP labels are used for products that call for the “no-label” look.

3. Size and Shape of Labels

Different products require different sizes and shapes of labels. The dimensions of the label of a cosmetic foundation will be radically different from that of a detergent. And, your choice of label applicator needs to adhere to the label specifications of the product. Some label applicators can handle only certain sizes and shapes of labels. So, you need to be mindful of your product requirements while making your final choice of label applicator.

4. Application Rate

In manufacturing units, the speed of production is a crucial factor. Companies spend a tremendous amount of resources to fast-track their processes to improve their operational speed. Applying labels is an integral part of the manufacturing cycle of products, so the total time taken at this stage can certainly make all the difference. All industrial label applicators have their own varying speeds when it comes to application rates. And, the application rate is usually measured in products per minute (PPM). Your choice of label applicator should match your production time targets. Ideally, it is best to go for a label applicator that would be flexible with regard to production time changes.

5. Capabilities

At the end of the day, it is your type of label that will dictate the type of label applicator you need. If you require specific capabilities such as large roll capacity, high application rate, and the ability to handle fancy label materials or large products, your application costs will likely increase. So, the more capabilities you require, the higher your label application costs.

Datong provides different high-quality labeling machines. For more information, please feel free to contact us.