5 reasons why you should consider the water filling machines

Views: 436

Author: Site Editor

Publish Time: 2021-05-08

Origin: Site

In the year 1621, some of the companies started selling bottled water. Before this era, nobody had ever thought that water could be packaged and sold. It was a risk worth taking, so the companies went on to manufacture bottled water manually. Nevertheless, their production and operation speed was slow initially, but it gained momentum with rising demand.

People started buying bottled water, and then in the 18th and 19th centuries, some manufacturers started the productization of mineral water and beverages. They started employing more workers to enhance productivity and sell their products as much as possible. Since the bottles were filled manually throughout the world, the supply was less, and the demand was rising.

Below are vital reasons that will encourage you to purchase water filling machine.

1.Increase production speed

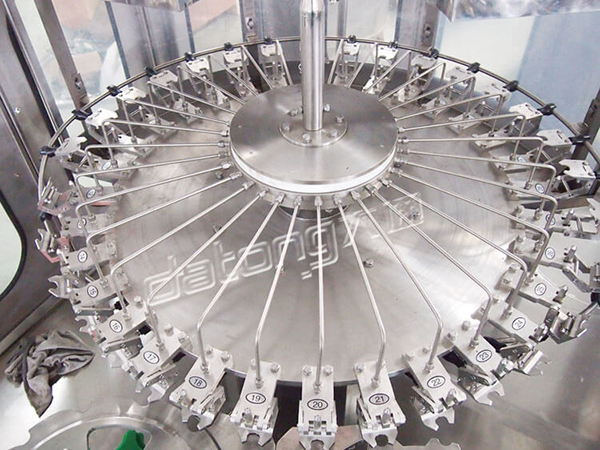

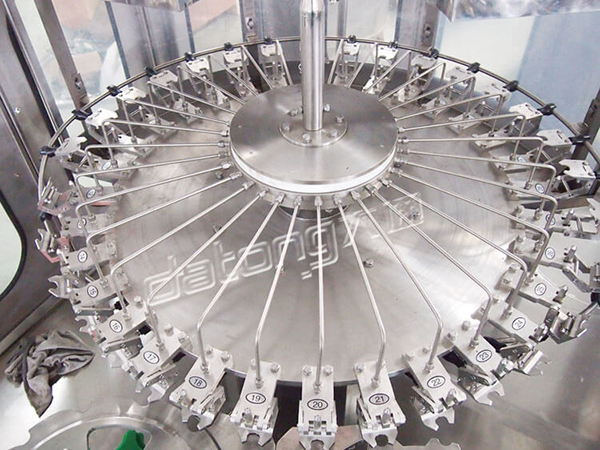

Water filling machines have the capacity to bottle several containers more compared to hand filling production. The speed can depend on the fill heads of the machine and the viscosity of the liquid. On average, a machine with sixteen fill heads can reach speeds of 120 bottles per minute, which can finish thousands of bottles each day.

2.Simple operating systems

Industrial liquid fillers may seem difficult to operate at first glance, but they come with operating systems that can be easily learned over time. Some bottling machines often only require simple adjustments to change one bottle to another. Water filling machines have input settings such as indexing times, fill times, and pump speeds.

3.Long Term Use

Industrial water filling machines are built to last for longer productions without wearing out. This ensures that you can keep your business running for a longer time. With proper monthly maintenance checks and a few workers alongside the process, you can save on daily expenses on time and energy.

4.Filling Versatility

Water filling machines don’t just bottle the same kind of product in the same type of container. When settings are adjusted, these bottling machines can fill any kind of product in any specific measurement. These machines are able to fill both thick and thin liquids, which benefits businesses with multiple lines of production looking for this industrial versatility feature.

5. Scalable

When production requires heavier assistance as the business grows, bottle filling machines can be upgraded without replacing the machine. Depending on the model, most industrial filling machines start with four to six filling heads. This can be added over time. Some models will have a maximum of sixteen fill heads.

Investing in machines for your business may be costly at the start. However, you will receive a return of investments once production begins to pick up. So if you can project the growth of your business, making the step to purchase this equipment is one step closer to greater success.

Contact us

If you're interested in any of our products, if you're looking for a reliable company, please don't hesitate to contact us. We will get back to you as soon as we get your inquiry. We can assure you that we will offer you the best price for high-quality products. We sincerely hope we can establish long-term cooperation with you.