Production process of beer

Views: 786

Author: Site Editor

Publish Time: 2019-05-28

Origin: Site

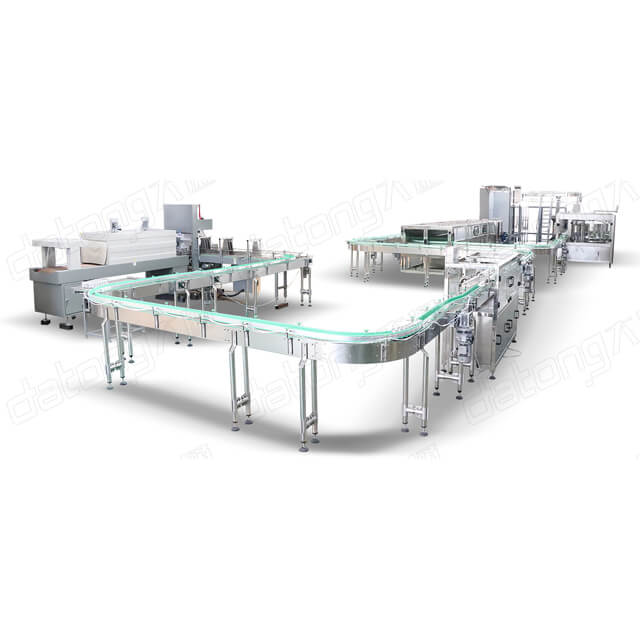

Many years ago beer was only available in some countries. Now, it is available around the globe because of its high demand. The demand for beer is increasing month by month. Due to this reason, the beer production companies are making use of automatic beer filling machine, beer bottling machine, and beer canning machine. All these machines can increase the production value to a high level.

Production Process of Beer

In almost every beer company, you will find a beer filling machine, beer bottling machine, and beer canning machine. All these machines have the latest technological innovation, which makes them efficient in every manner. They are pretty easy to use. It can perform different tasks, so the companies do not need to hire many labors. In this way, they will be able to save labor costs.

At present, we are going to discuss the production process of beer. Well, it is simple and easy to understand. Have a look at the following steps to learn about it:

Malting

The first step of beer production is malting. Every beer has some grain. Most companies make beer from barley while others use wheat. However, in this phase, the machine dries the grains and cracks them up in a heating procedure. When these grains open the enzymes isolate, which ensures that they are ready for mashing.

Mashing

In this phase, the enzymes of the grains add up into the hot water. With the help of steeping on the grains, they leave sugar into the water and get ready for the process of fermentation. Nonetheless, the steeping and mashing process takes three to four hours. When the steeping is complete, a worker takes out the grains from the sugary water.

Boiling

In the boiling process, the spices and hops add up into the hot water, and then the machine boils them properly. This process takes only half an hour and finishes when the full flavor of the spices and hops comes out.

Fermentation

In the fermentation phase, the machine produces alcohol for the beer. Till this step, no alcohol is present in the beer mixture. It is essential to add yeast as a catalyst to begin the process of fermentation. The yeast reacts with the sugar to make alcohol. This process is time-consuming. It takes around four to five weeks. When the wort ferments completely, then the alcohol content produces.

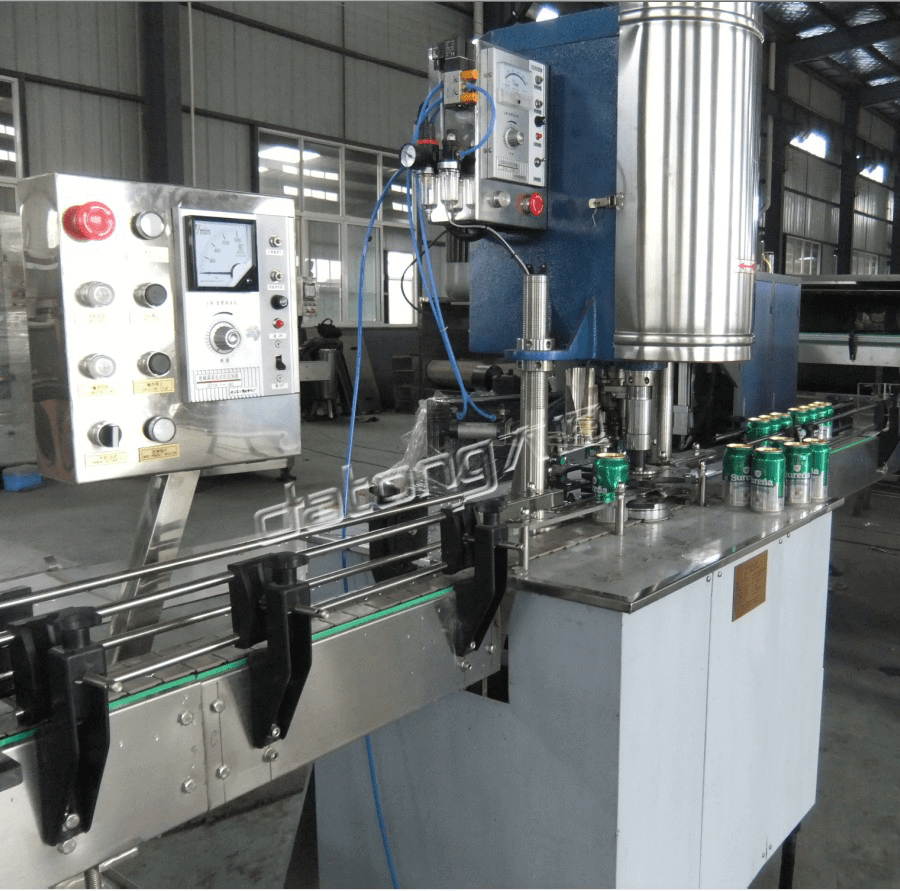

Filling & Canning

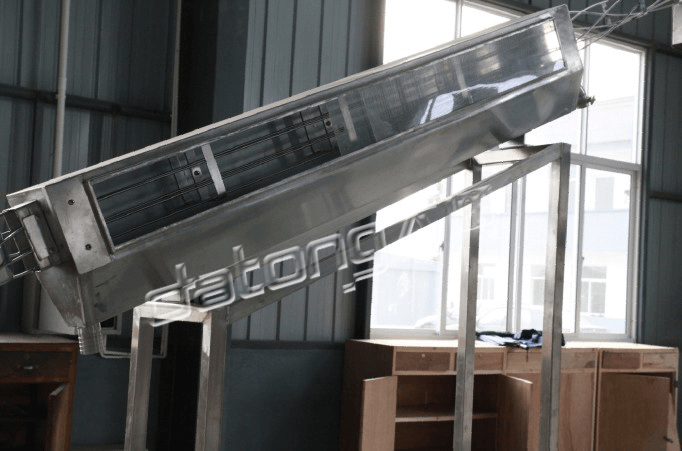

When the alcohol adds up in the beer mixture, then the beer is ready to fill up into the cans and bottles. The beer filling machine fills up each can and bottle correctly. After that, the beer bottling machine puts a cap on the bottles to seal them up. On the other hand, the beer canning machine seals the cans. When these cans and bottles of beer seal appropriately, then the conveyor takes them to the packaging area. In this packaging area, the machine picks the cans and bottles one by one and put them in a shipping box. It places the cans in one box and bottles in the other one. When these boxes are ready, then the company ships them to different places across the globe.