About DATONG:

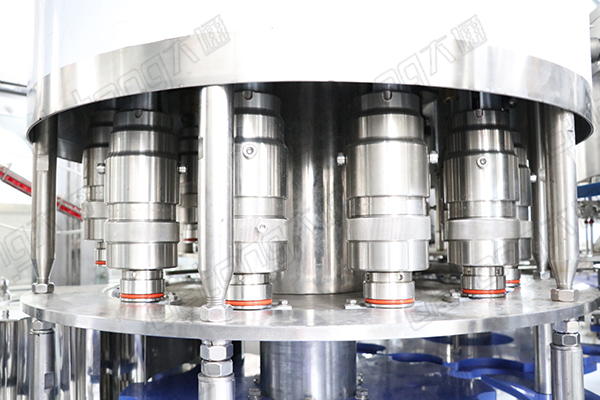

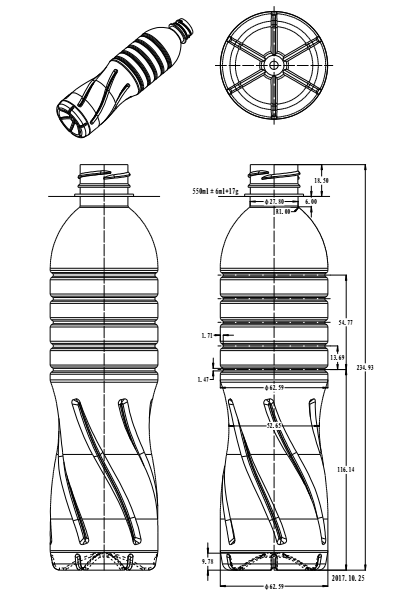

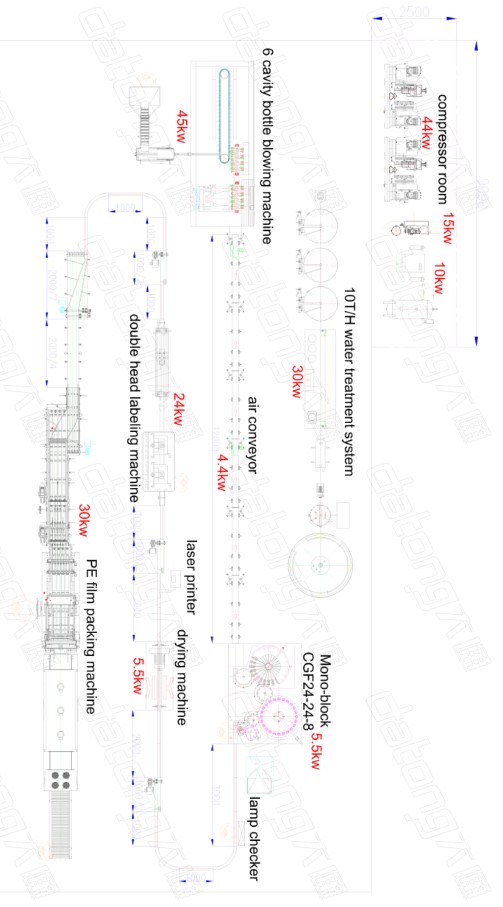

Founded in 2002, Modern factory of 6000 square meters, the company has professional technical force in filling, blow molding, labeling, packaging machinery and technology of water, tea, fruit juice, carbonated beverage, energy beverage, liquid beverage, beer, edible oil and other products.

Advantage:

1.More than 18 years of market experience.

2.Different options can be chosen.

3.Over 40 countries use our machines.

4.The supplier is ourselves.

5.provide 24 months long warranty, free parts and effective service

6.We have the equipment certification certificate:CE,ISO,SGS,TUV

Certificate

our sample project

|

|

|

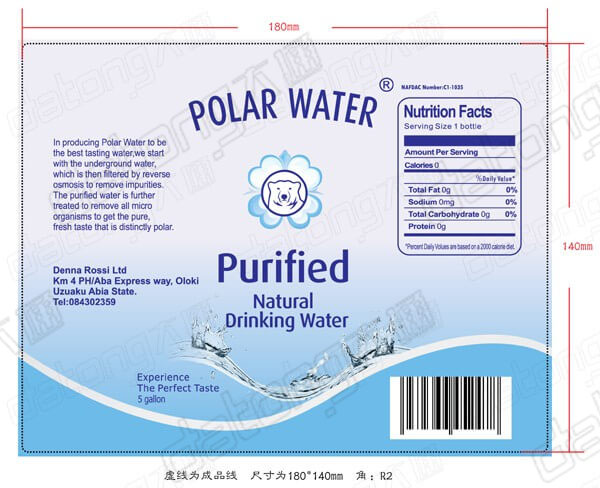

| 5 gallon line | canning line | water filling line |

Do you need more information? We will be pleased to help you!

Fill in the contact form or contact us by phone +86-512-58662088 or email lynn@datong-machine.com

Contact us