Max package dimension:L420×W278×H390mm

Min package dimension:L210×W140×H100mm

Material of shrink film:PE、PVC

Thickness of shrink film:0.03—0.15mm(special demand shall be proposed for special making)

Thermal shrink temperature:it can be adjusted freely under 260℃.

Max capacity per minute: 12-18 bags/min

Total heating power:57.6kw

Suitable voltage:380/220V

Working air pressure 0.6-0.8Mpa,air consumption capacity: 0.3m3/min。

Gross weight:5150KG

Machine dimensions: 11850×1315×2150mm

DATONG service

|

|

|

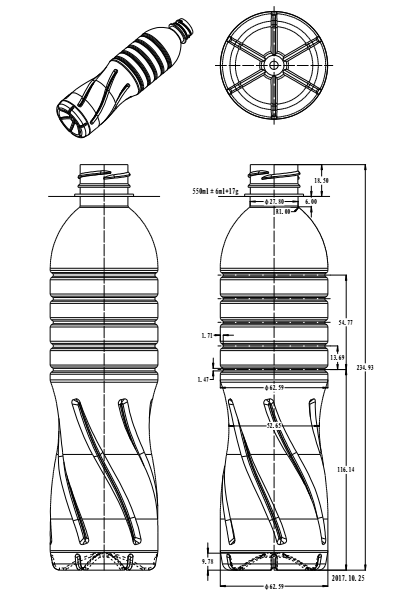

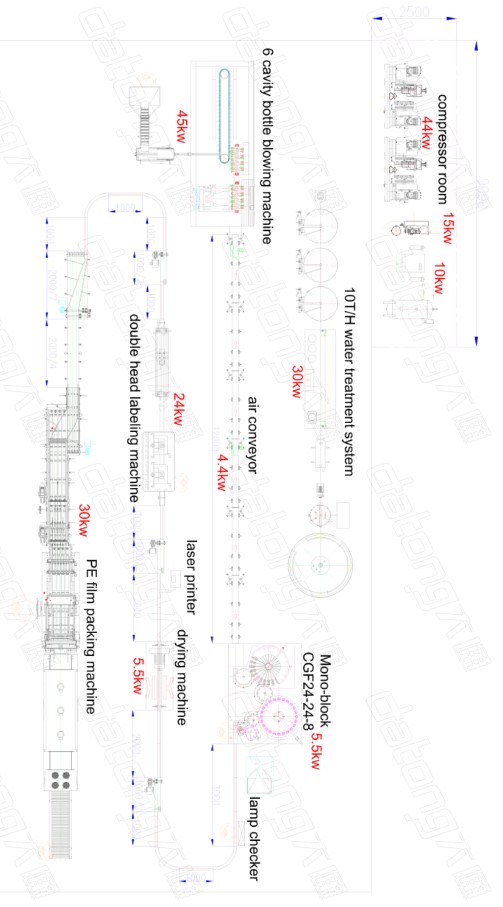

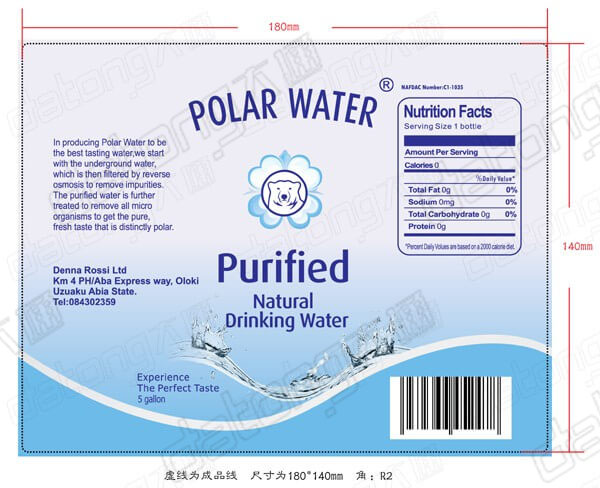

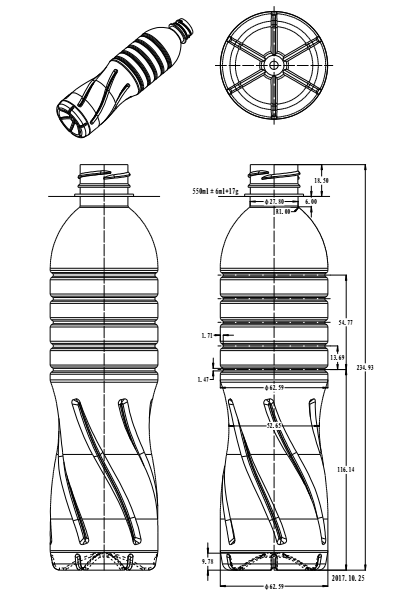

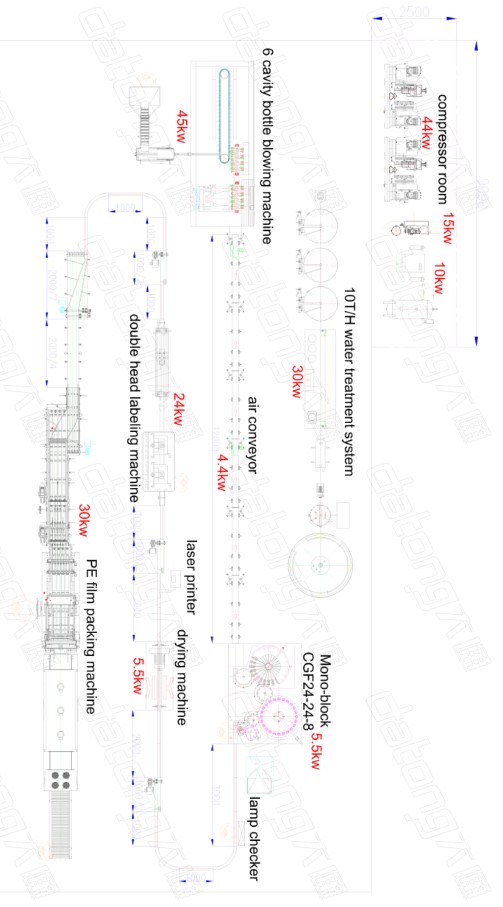

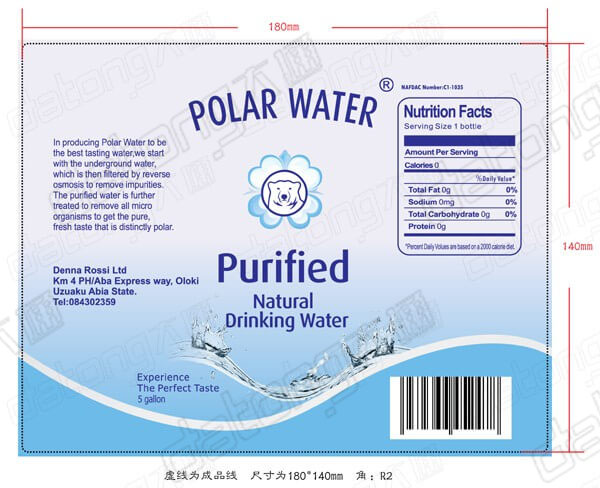

Our engineer can design different bottle drawing for your reference!Contact Us: We will send design drawing! | We supply standard layout for each water filling machine line,also available for customize design layout based on Customers Factory Area! | Design colorful label for customers choice.

Provide Us: Information want to put on label. |

befor sales:As for any questions you may have, our foreign trade specialist will reply within 24 hours and can show you more videos of operation and detailed pictures of the products.

on sales: We will update the production schedule weekly, send pictures of production, run machine tests before shipment, and send videos

after sales: We will arrange engineers to install the machines and provide accessories. Please call the after-sales service hotline at 0086-512-58662088

Our technicians have a lot of work experience, they often tell themselves:

see difficulties as:the test is in a way

cooperation is the foundation of our succes

personal shortcomings is not terrible,the key is to see

the good in people,control yourself

do not crazy big,succeeded because a group of people are very great

arrogance often because their performances exceeded his expectations,should see further