Fruit for juice processing with sugar tank

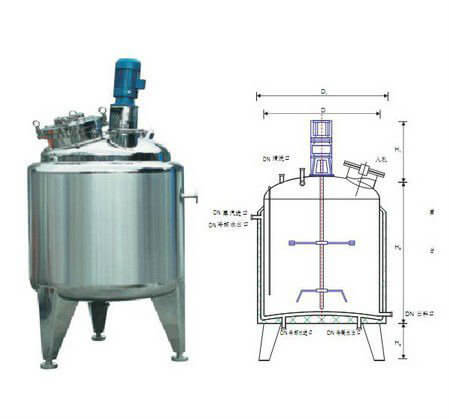

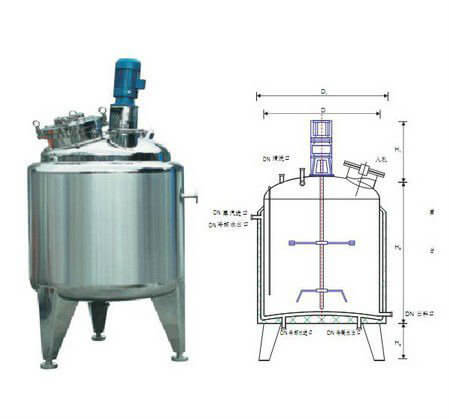

Sugar melting tank:

Sugar Melting Boiler is a new type of beverage machinery. This machine can finish the sugar melting work by electricity or steam heating, with stirring motor. The body of the boiler is composed of cylindrical stainless steel inner seal head, thus forming a heat transfer sandwich. Packaged by the stainless steel outside, the Sugar Melting Boiler is generous in appearance. Putting the melting material and cold water in the boiler and making the steam pass through the sandwich can accomplish the goal of heating and melting. The conduit united with the sandwich is equipped with pressure gage and safety valve, which can mensurate the pressure and guarantee the safety.

Sugar melting tank features:

Sugar Melting Boiler is used in the melting, disinfection, cooking, heating and insulation of dairy products, syrup, fruit juice, food and so on.

cylindrical stainless steel inner seal head, thus forming a heat transfer sandwich. Packaged by the stainless steel outside, the Sugar Melting Boiler is generous in appearance. Putting the melting material and cold water in the boiler and making the steam pass through the sandwich can accomplish the goal of heating and melting. The conduit united with the sandwich is equipped with pressure gage and safety valve, which can mensurate the pressure and guarantee the safety.

Mixing tank :