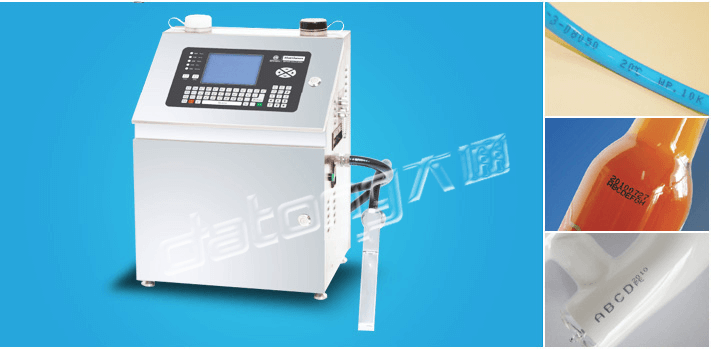

Cans unloading machine

Information:

Automatic destacking machine is mainly used for round tank automatic destacking, empty cans will be stacked on the pallet, ascension by unloading tank body after push the cans layers of tank device push to mesh conveyor platform, temporary buffer.On one side of the net conveyor chain, there is a conveyor belt, which is carried by the conveyor belt into the slide wash tank.

The machine can replace artificial can, improve the production efficiency and the degree of automation.It has the characteristics of high precision, stable can, and continuous adjustable production speed.The machine USES variable frequency control, the action adopts PLC centralized control, the electrical and pneumatic elements are foreign imported components.

Production capacity: 200 cans / min

Applicable diameter: 52-153mm

Applicable tank height: 39-170mm

Pushing tank type: automatic pushing tank, net belt conveying

Tank type: multi row, single row, conveyor belt, out of pot

Raised form: automatic

Overall power: 3.5KW

Size: 8.3x4.5x3.2

Whole machine weight: 3 tons