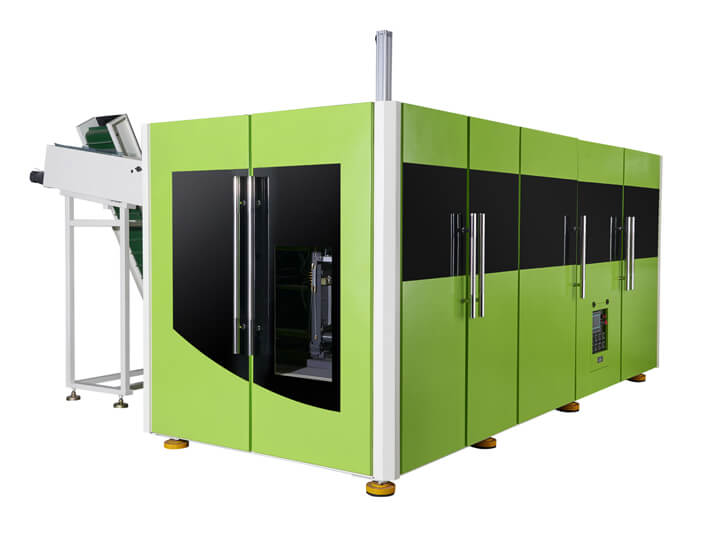

Best selling semi automatic bottle blowing machine for drink water

Semi automatic bottle blowing machine:

1. Double crank arm for mold locking reaches high mold-locking strength and flexible action.

2. Use PLC for control (time relay control optional), easy repair, low cost, with the time controllable accurately in 0.0ls..

3. The gas circuit consists of moving and blowing so as to satisfy the different air demand of them.

4. The far-infrared heater uses a way of conversion self-rotating heating and the rail revolution makes the heating even, quick and reliable.

5. Every heating lamp has independent temperature control device, to get ideal preform heating effect.

6.T he direction of the heating lamp is adjustable upon different preforms.

7. Only need two operator, do not need special training. Simple installing and starting.

| ITEM |

| Unit | DT-1 | DT-2 | DT-1-20 |

| Theoretical output | Pcs/h | 900 | 1800 | 90 |

Product

| Volume | ml | 200-2000 | 200-2000 | 20000 |

| Max.height | mm | 360 | 360 | 550 |

| Max.diameter | mm | 105 | 105 | 300 |

Mould

| Number of cavities | / | 2 | 2 | 1 |

Mould plate dimension (L*H) | mm | 490*450 | 490*450 | 620*620 |

| Mould thickness | mm | 220 | 220 | 380 |

| Mould opening stroke | mm | 180 | 180 | 360 |

Power Electrical | Voltage/frequency |

| 380V/50HZ | 380V/50HZ | 380V/50HZ |

| Total power | KW | 11 | 21 | 36 |

| Heating power | KW | 10 | 20 | 35 |

Machine

| Main body dimension (L*W*H) | M | 1.5*0.65*2.0 | 1.5*0.65*2.0 | 2.1*0.75*1.8 |

| Main body weight | KG | 550 | 550 | 900 |

| Pre-heater(L*W*H) | M | 1.4*0.65*1.5 | 1.8*0.65*1.5 | 2.7*0.7*1.6 |

| Pre-heater weight | KG | 300 | 350 | 400 |

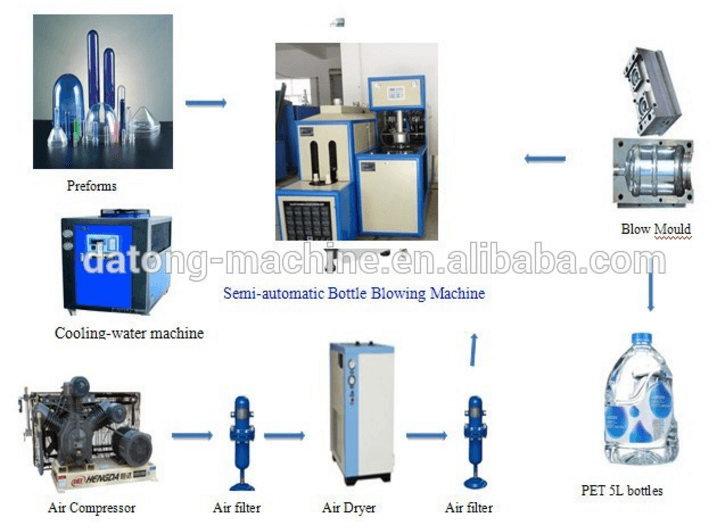

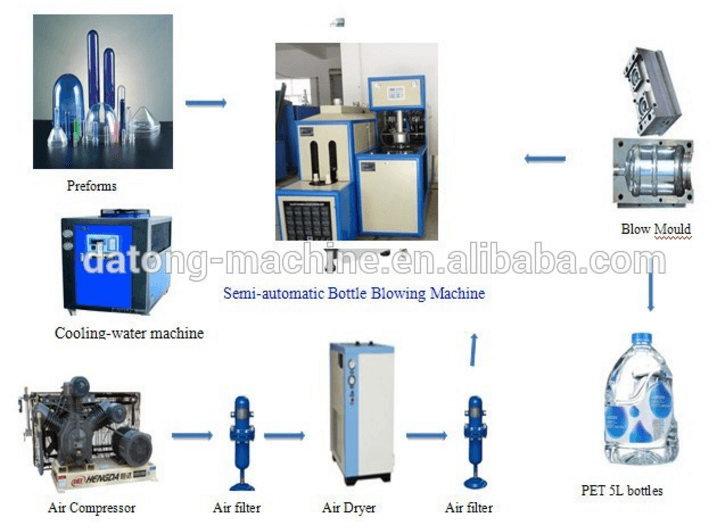

Semi automatic bottle blowing machine flow chart:

Some bottle molds and Preforms: