The Future Development Trends of Can Filling Machine

Views: 721

Author: Site Editor

Publish Time: 2019-08-30

Origin: Site

Many people ask about the future development trends of can filling machine. Well, it is a big concern for different industries and people who are inclined towards the filling industry. At the present time, we are going to discuss these trends in detail.

Presently, beverage and food industries are making use of the can filling machine. The demand for this machine is rising because the cosmetic industry is also getting interested in it. The competition is getting tough little by little. The food and beverage filling machines will get involved in the automation industry in the future.

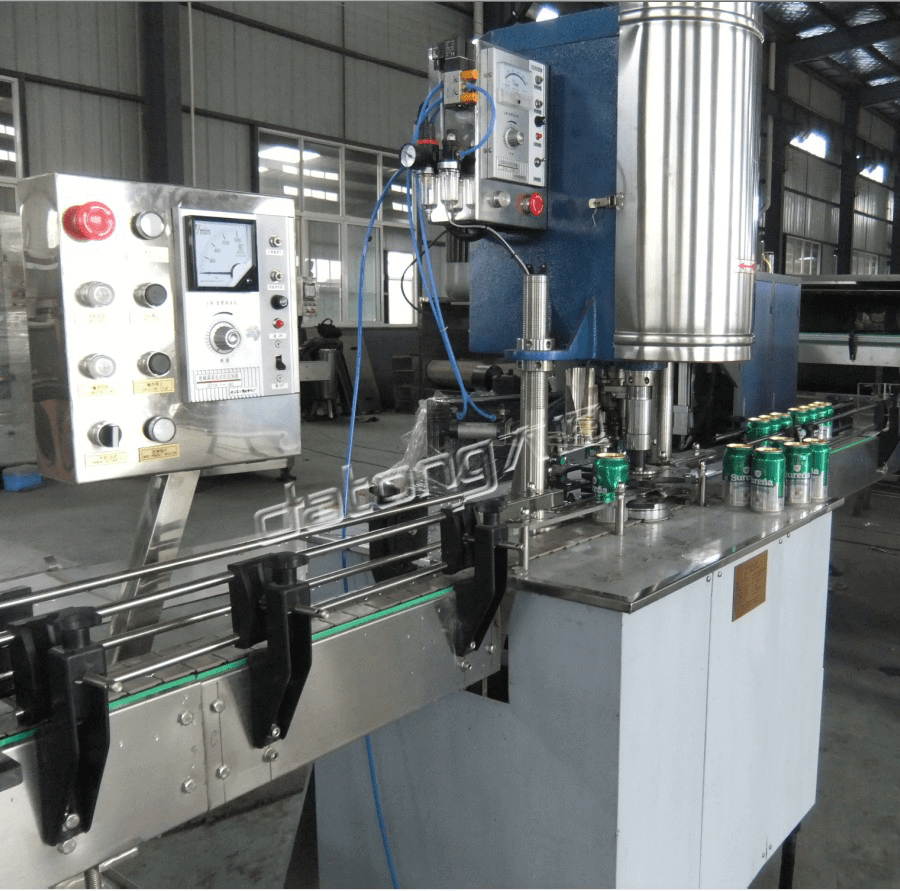

The aluminum can filling machine is standing well in the beverage market because of its modern technology. The manufacturers are using modern devices in these machines to increase their efficiency. Modern people who are concerned about the quality of products are behind the popularity and demand of this machine. In a couple of years, science and technology are becoming better which is directly having an impact on the filling machine market.

What about the filling machine development in future?

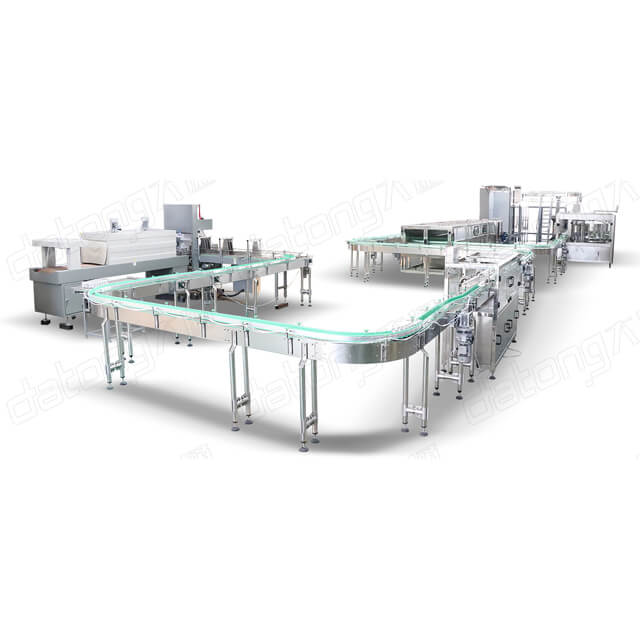

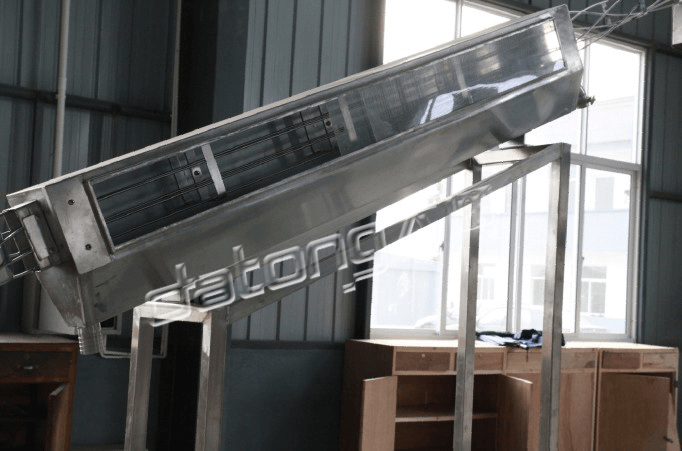

Firstly, it is imperative to understand the characteristics of a filling machine. It does not matter if it is a simple or beer can filling machine; you need to know its characteristics. The filling machine picks empty bottles one by one. There are a conveyor and filling head incorporated in it. The conveyor’s role is to take the bottles from the first section to the last. The bottles or cans are first cleaned up properly. After that, they are taken to the filling section. There is a filling head that fills each can or bottle with the beverage up to a particular level. There was a time when the companies could not adjust the level of the beverage in the bottles and cans. However, with the help of latest technology, the companies can easily adjust the level according to their requirements.

The filling head of the automatic filling machine fills each bottle and can. After filling, the conveyor takes these bottles and cans to the packaging section. The cans and bottles are properly closed in this section. The machine picks each can or bottle one by one and put them in the cartons. There is a different place for cans and bottles in the cartons. The machine automatically places these containers in their particular sections. When all sections are filled then the cartons are wrapped up. The workers take these cartons to the distribution area.

In the future, the filling machine will not just be able to fill the containers, but it will also have the capacity to make the beverage. In this way, the companies will no longer need beverage making machinery. This machine will become efficient enough to perform all the tasks. Furthermore, the manufacturers will add up various features in these machines to make them more independent and efficient.

Final Words

In the future, the manufacturers will add up smart technological devices in the machinery to make it competent. It will assuredly have an impact on the can filling machine price. The price of the machine will rise with an increase in features. However, these devices might cut out the maintenance cost.