Some Frequently Asked Questions About Can Filling Machines

Views: 382

Author: Site Editor

Publish Time: 2022-06-06

Origin: Site

Many customers consider investing such a large sum of money to purchase a can-filling machine to be an overwhelming proposition that requires proper planning and management. As a result, they go the extra mile to ask a few questions to gain a better grasp of what it entails before purchasing it.

Well, if you're one of such customers, then you are at the right place. I will be sharing in this post, some frequently asked questions about the can filling machine, along with their responses to help you make informed decisions when purchasing a can filling machine.

However, you should know that getting a can filling machine from an experienced and dependable manufacturer is of great importance as only with this can you be very sure you are making a profitable purchase. I hope you find this post informative. Let’s dive right in

Frequently Asked Questions about Can Filling Machine

What is a can filling machine used for?

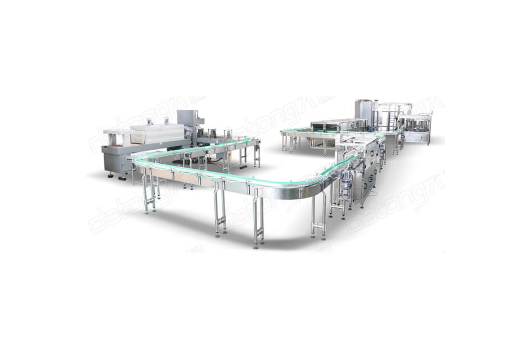

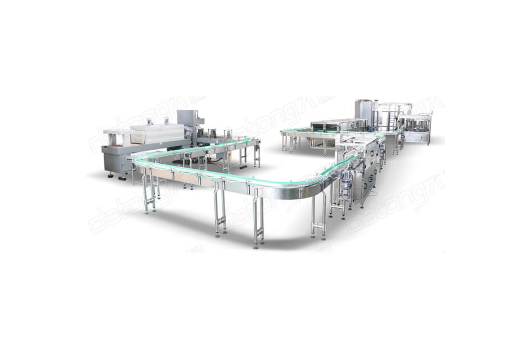

A can filling machine is a type of automatic filling and capping machine used for filling and covering processes in the production of different beverage drinks ranging from beer, carbonated drinks, juice drinks, energy drinks, and soda water.

How does buying a can filling machine benefit my beverage business?

The can filling machine has many benefits, including stable operation, good sealing quality, appealing appearance, the convenience of use and maintenance, touch screen operation, and frequency conversion speed modification.

However, the most promising benefit of a can filling machine is that it helps to increase the speed of your production as it has several fill hands that have the capacity to fill several cans at a specific time compared to what filling with your hands will do. Although, the speed of production is largely determined by the viscosity of the drink you are producing.

Is a can filling machine easy to operate?

Due to the coupling of high-level automation technologies and a high degree of accuracy introduced in the make-up of can filling machines, its use has been made simple and straightforward to operate by merely looking at the device's settings.

What is the maintenance of a can filling machine like?

Maintaining can filling machines are not quite difficult. It involves;

· Proper cleaning of the machine prior to usage and after usage

· Regular inspection and servicing of the can filling machine.

· Regular checking of the delicate parts of the can filling machine prone to wearing and adequate replacement of worn parts as soon as possible.

· Regularly lubricating the machine.

What is the power usage of a can filling machine like?

On average, the power consumption of a can filling machine is 5.5KW/H.

What should I consider before purchasing a can filling machine?

Before diving straightway into the purchase of a can filling machine, there are some things you need to consider to inform your decision of which type of can filling machine you should purchase. Things to consider include;

· The nature and viscosity of your beverage product: Whether your product is water-like, semi-viscous, or viscous.

· The shape, size, and strength of the type of filling cans: Whether they are tall or short, big or small, strong or weak, round or square, rigid or flexible cans.

In need of a premium can filling machine

Without a doubt, getting a can filling machine is important for your beverage production line. Hence you need to choose to buy from the best.

With over a decade of knowledge and experience, Datong Machinery is committed to providing high-quality can filling machines backed with first-class service.

Kindly reach out to us for the purchase of your can filling machine.