Print and Apply Labeler - 10 Tips for Choosing a Labeling Machine

Views: 743

Author: Site Editor

Publish Time: 2019-04-16

Origin: Site

1. Identify your Product:

The type of material you are producing and you which to label is essential in determining the type of machine required for the labeling perfection. This means the texture of your packaging material is one of the things you need to check before choosing a labeling machine.

2. Rate of Application:

The rate of application talks about the speed of attaching these labels. It is necessary for you to understand that the rate of application is the factor that would determine the speed settings needed. After calculating the speed, which is based on products per minute, you can easily identify your choice of labeling machine using product rate requirements. If the machine does not meet up with the specification, then it is not the best choice for you.

3. Labeling Materials:

It is vital to put the type of labeling material you which to use into significant consideration because not all labeling machines can work correctly with a wide range of material. To get a machine that would give maximum performance, you need to know which machine can work with your choice of material without a problem.

4. Machine Supplier:

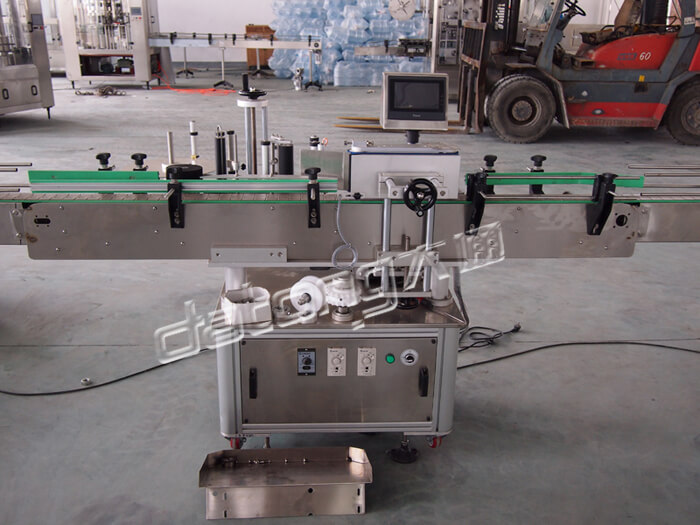

Before purchasing any sticker label machine from any manufacturer, there is a need for you to consider some factors such as reputation and recommendation. If the manufacturer is known for supplying materials that barely last long or even give a performance that matches the amount you are paying, then you need to reconsider your choice and look for a better manufacturer. However, if this is a difficulty, I have a solution. Datong machines. This is a reputable company with an excellent record of sales of the best types of equipment, which includes filling machines. A visit to the physical location or a good use of their website is all you need to escape from the nightmare of falling victim of fake product.

5. Label Location:

a perfect labeling machine for your product is that which can appropriately fix/attach a label to any part of your product that you which for it to attach the label. If it cannot do that, then it is not the machine you need for adding a label to your product.

6. Maintenance:

Maintenance of a labeling machine is a great determinant of the durability and a determinant of the flow of income. The reason it affects income is that if maintenance is too expensive and you have no choice than to do it, it will reduce profit because you will have to spend it on the machine.

7. Price:

It is not in all cases that we can easily afford what we desire. If the price of the labeling machine is too high and you don’t intend to tamper with your capital, then you need to choose a labeling machine you can pay for easily.

8. Size:

The container size would affect the quality of the labeling. This makes it essential to consider if the labeling machine can work well with it before choosing the device.

9. Shape:

Different containers have different shapes, which must be considered to be certain the label machine can work correctly with it.

10. Durability:

If you will need to buy a new one in just a few months after purchase, then wasting your money is not worth it.