Carbonated beverage filling machine has great potential

Views: 657

Author: Site Editor

Publish Time: 2020-06-05

Origin: Site

With the development of technology and the increasing demand for carbonated beverages, the demand for carbonated beverage filling machines is also increasing. Using carbonated beverage filling machine can not only greatly reduce labor costs, but also greatly improve production efficiency and increase corporate profits. Therefore, we can say that carbonated beverage filling machines have great market potential.

Now, let's introduce DATONG, a carbonated drink filling machine factory specializing in the production of carbonated beverage filling machines and its different products. Our carbonated drink filling machine factory is specifically manufactured to accommodate the exacting needs of each customer, resulting in a bespoke system tailored to their requirements. Such an approach has established DATONG as a worldwide market leader.We are committed to exceeding the expectations of our customers by combining a superior level of expertise with high quality products, all backed by first-class service.

The basic introduction of carbonated beverage filling machine is as follows

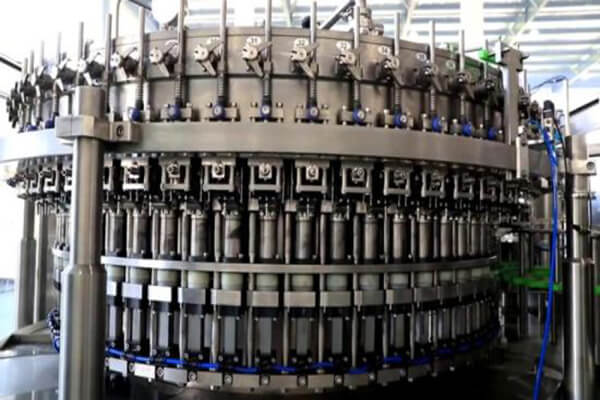

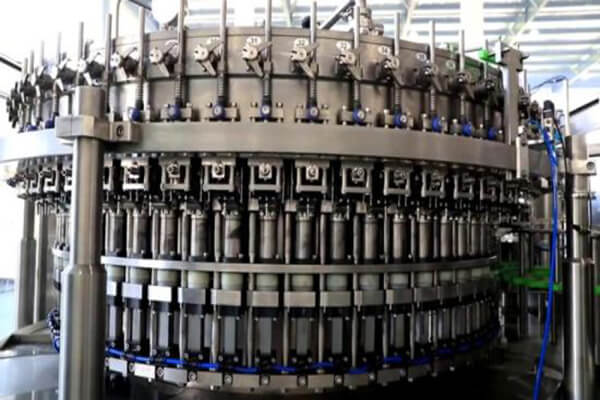

Carbonated Beverage Bottle Filling Machine could be separated to 3 modules. The height of the bottle-out conveyor is adjustable.bottles are conveyed to rinser,filler and capper through starwheel and conveyed out finally through bottle-out conveyor.equip alarm device for bottle block,bottle absence,cap absence and overload.the machine meets the national food hygienic standard,with high automation and easy to operate.

It adopts technology of air conveyor direct connect with bottle infeed starwheel to instead of screw and conveyor.it is easier and more simple to change over bottle size. Adopt neck handling technology to convey bottles.there is no need to adjust the height of equipment and only need to change some spare parts.

By 3-in-1 monoblock ,the bottle goes through washing,filling and capping with little abrasion,and the transferring is stable,bottle changing is easier. Specially designed stainless steel bottle gripper dose not contact the thread parts of the bottle neck,avoiding the second contamination. Pressure liquid carousel.High speed and mass flow filling valve ensures the high filling speed and exact fluid level.parts contacting liquid are all made of excellent stainless steel or food grade engineering plastic.the electric system is from international brand and achieves the national food hygienic standard.the bottle-out starwheel is helical structure.while changing over bottle size. It is no need to adjust bottle-out conveyor height.

That’s the basic introduction of carbonated beverage filling machine and our carbonated drink filling machine factory and why it has so much potential. If you encounter any problems about anything, please feel free to send us inquiry and we will do our best to assist you to solve the issue.