Can Filling Machine Safety Tips

Views: 365

Author: Site Editor

Publish Time: 2023-01-09

Origin: Site

If you're looking for tips on how to keep your filling machine safe, then this is the post for you. There are a ton of things to look out for when operating a filling machine and even more ways that accidents can happen.

We'll go over some of those common safety tips that can help you prevent accidents when using a can-filling machine. If there's one thing that these tips will help you avoid, it's getting hurt or injured while working around this machinery. So, let's dive in.

1. Wear Appropriate Personal Protective Equipment (PPE)

Personal protective equipment (PPE) is critical for safety. It should be comfortable and fit well, but it also needs to be appropriate for the task at hand.

The best PPE for this job is a pair of gloves, goggles, and earplugs—but you should always wear your PPE when operating the machine, cleaning up after a spill, or performing maintenance on your filling machine.

2. Follow All Safety Procedures and Guidelines as Outlined in The Machine's Operating Manual

Read the manual before operating the machine, especially if you are new to filling machines or do not have experience with them. Filling machines require different safety precautions than other types of equipment, so it’s important to follow all instructions carefully.

Always follow good manufacturing practices (GMPs) when using your filling machine. These include using appropriate materials and following quality assurance standards for both production materials and finished products being produced by this type of equipment.

3. Keep All Electrical Panels and Connections Secure and Dry

Keep electrical panels and connections dry. Electrical panels can be damaged by both water and moisture, so it's important to make sure they're not exposed to either of these things.

If a panel is wet or has been exposed to excess moisture, it will corrode quickly and become useless. Secure all electrical connections properly by wrapping them in tape or other non-conductive material before putting them away for storage.

This prevents accidental shorts that could lead to fire hazards if left unsecured for long periods (and also makes sure your equipment works properly).

4. Always Follow Good Manufacturing Practices to Ensure that The Product Being Filled is Safe and of High Quality

Follow the manufacturer's instructions on how to fill your can. If they tell you to use a certain size of the can, then do so.

This not only ensures that you're putting the right amount of product into each container but also makes sure that there aren't any air bubbles entering through gaps between parts or cracks in the lid (which could lead to liquid spilling).

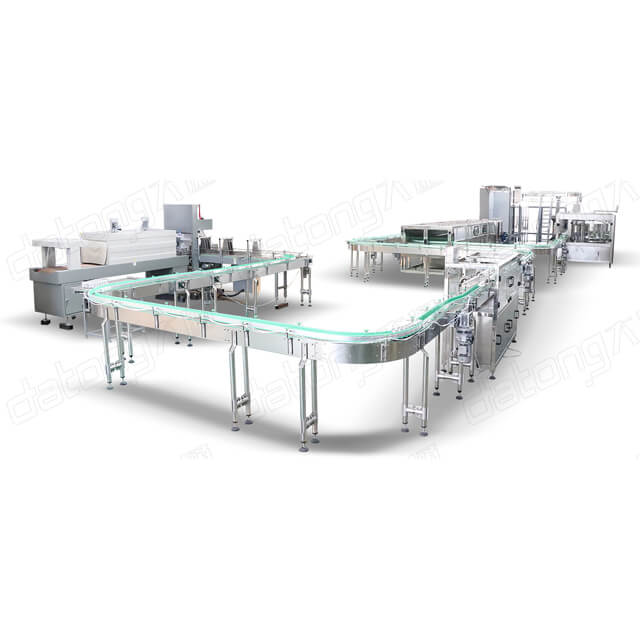

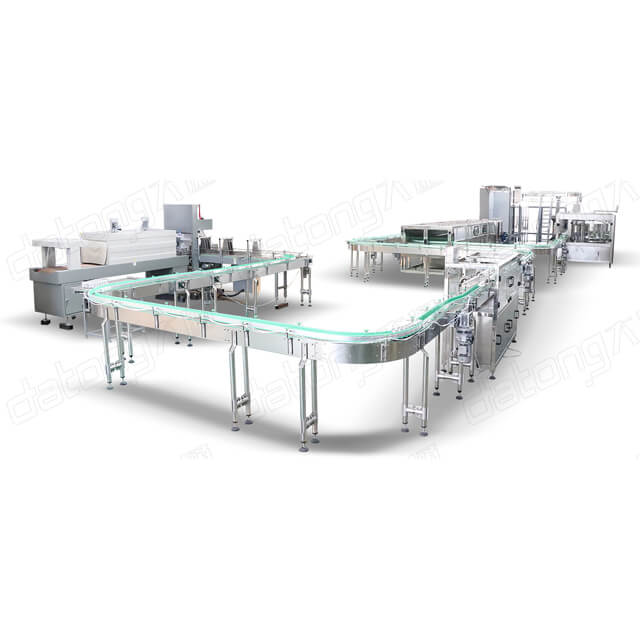

Purchase Your Can Filling Machine from Us

If you're looking for the best can-filling machine, then look no further than us. We have the most affordable prices on top-quality products. Plus, our customer service is second to none. We'll work with you every step of the way until your order is complete and in your hands.

We're confident that you'll be satisfied with our can-filling machines, but if there's ever any issue, we'll work with you until it's resolved. If you are ready to place an order, kindly click here.