Bottling Vs Canning: Which is Best for Your Beer Business?

Views: 1137

Author: Site Editor

Publish Time: 2017-12-13

Origin: Site

To can or not to can? This is the big question on craft beer brewer’s lips, and it’s not surprising, given the sudden surge in popularity of canned craft beers in the US. Canning independently brewed beers somewhat flies in the face of convention; traditionally, craft beers came in bottles, as a mark of their quality and status as an ‘artisan’ product.

However, there’s no denying there’s potentially big bucks to be made from canning your craft beer. If you’re struggling to decide which is best for your business, here’s a brief guide, outlining the pros and cons of each packaging solution.

Cans Vs Bottles: Which is Better?

Protection of beer

The most widespread argument for cans is that they're made for protecting the booze inside. Beer's biggest enemies are light, oxygen, and heat. The good news for bottles is that amber glass blocks around 99% of the wavelengths of light that will damage your brew, and recent packaging modifications that cover beer for most of its moving life don't necessarily make this round an instant KO for aluminum… though cans trounce green, blue, and clear bottles when it comes to keeping the light out.

Weight and portability

Let's take a look at some numbers, shall we?

Approximate weight of a six-pack of 12oz canned beer: 5lbs

Approximate weight of a six-pack of 12oz bottled beer: 7.5lbs

The difference seems almost negligible in the store, but just wait 'til you're two miles into your hike with a six-pack of longnecks in your backpack, or lugging a case of bottles to your friend's BBQ. Ten extra pounds of bottles makes a huge difference.

Environmental impact

The one isn't all that close. Cans weigh as much as 10lbs less per case, which seriously cuts down on shipping fuel use. They’re also smaller in physical size, so many more can be shipped at once. And the recycling process makes cans easier to deal with in many areas (which is why close to 70% of all cans are recycled). This is a slam dunk of Captain Planet proportions for cans.

Labeling and Price

Cans are cheaper. There’s no doubt about it, cans work out cheaper than bottles. However, it’s more likely that you’ll have to do larger runs; which isn’t ideal if you don’t want to produce in bulk. Bottles offer flexibility with labeling. If you’re a small-scale brewery and you want to offer several products, it’s easy enough to use the same bottle each time, just with different labels. With cans, however, you’ll need to reprint the design, which can get costly; though choosing to use a shrink-wrap label can help reduce costs. Bottles have the edge when it comes to appearance.

Generally, bottles are still associated with higher quality products, which enables breweries to increase prices, should they want to. Cans offer mobile appeal. One of the distinct advantages of cans for the consumer is that he or she can easily carry them on picnics, hiking trips or to festivals. After consuming, they’re easy to crush into a compact, lightweight size; unlike bottles.

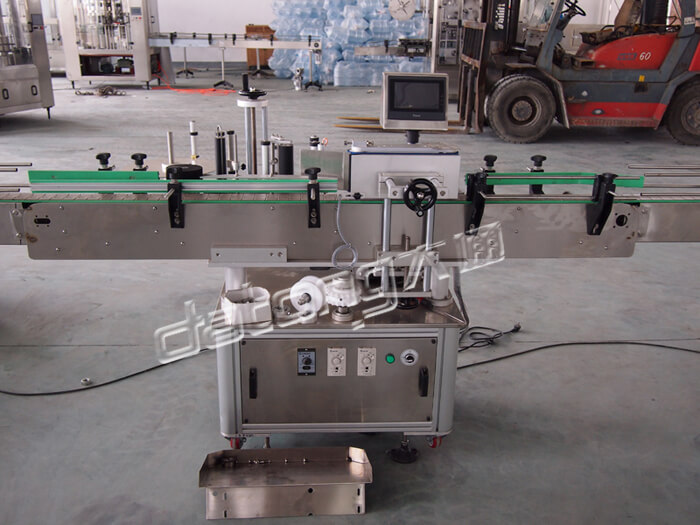

Unsure? Ask Around! If you’re not sure what’s going to work best for your business, the best thing to do is talk to other breweries, or discuss your options with specialist suppliers of filling and labeling machines, such as us, who will be able to outline the advantages and disadvantages in more depth. To request a free quote or simple ask us a few questions, contact us now, Find by liquid.