Bottle Labelers Are Available for All Sizes of Manufacturing Units

Views: 640

Author: Site Editor

Publish Time: 2018-09-17

Origin: Site

A label is a small piece of paper, fabric, plastic, or similar material that gives a vivid information about a product or item. Labels are usually attached to the container or product which it describes. When the information is printed directly on the container, it is referred to as labeling. There are labelers available for all sizes of manufacturing unit, although. it might be challenging finding the best label and even more difficult in bottles.

Important functions of labeling:

• It provides the necessary information about a product and also the contents contained in it

• Labeling makes it easier to identify different products or brand.

• Labeling makes it possible to categorize different qualities of the same product.

• Labeling helps to promote the sales of products as it may sometimes attract customers because of its design.

Typical Kinds of Label Materials

Coated paper labels

This kind of label is designed with a coating applied onto one side. It is the lightest amongst other labels.

Laminated paper labels

This kind of label is built by joining two or more layers of very thin plastic together. This makes it a bit higher than coated paper labels.

Polypropylene labels

This is more advanced in nature as it provides resistance to heat, cold, and tearing. This particular label material is made up of a thermoplastic substrate.

Synthetic composite labels

This kind of label has a more strong, durable, and water-resistant nature. It has an appearance of a heavyweight paper and as such, takes printing like a paper.

Things to consider when making a label

Measure your item:

It is important to know the product or item on which the label will be attached before you begin the design of the label.

Picking the right label size:

Here, one has to consider the overall view of the item once the label is attached. The margins and the space provided should be well calculated.

Coming up with the right design

The design of your label should be dependent on your objective for making the label and as such, should match your intent.

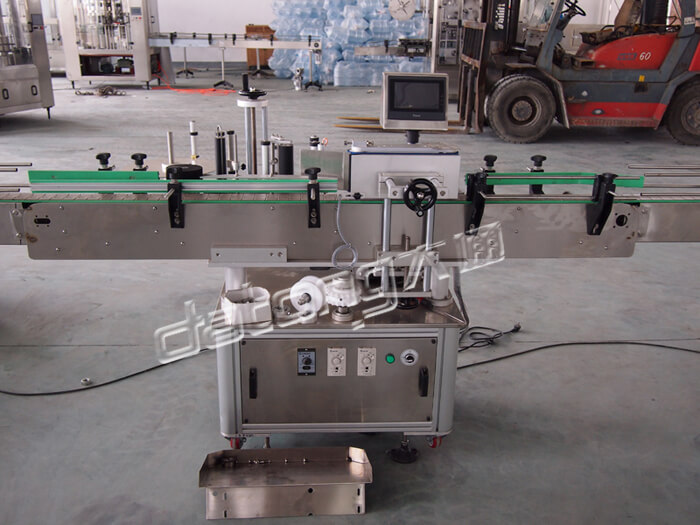

Bottle Labeling Machines

ZL5 Label Applicator Machine for Round, Square & Oval Bottles, Boxes:

This is one of the most versatile bottle labeling machine.

Semi-Automatic Round Bottle Labeling Machine:

This machine is best used for round bottles such as PET bottles, glass bottles, and metal bottles.

Bottle Label Applicator Machine for Small Home Businesses HC6:

This bottle labeler does everything that an expensive manual labelling machine does.

START International LAB01 Manual Bottle Label Applicator:

This labeler is to label bottles, cans, and other cylindrical objects.