Bottle Blow Molding Machine Process

Views: 427

Author: Site Editor

Publish Time: 2023-03-07

Origin: Site

Blow molding is a broad name for the process of creating hollow plastic parts by inflating a viscous plastic tube, or parison until it fills a mold and takes on the required shape. Consider it similar to inflating a balloon inside a water bottle.

There are three main ways to blow mold: by injection, by stretching, and by extrusion. Water bottles, cosmetic containers, and other small hollow pieces are frequently made using injection and stretch blow molding.

Read on as the process of extrusion blow molding is going to be discussed in this article.

Extrusion Blow Molding Process

The creation of a viscous plastic tube, sometimes known as a "parison," and its extrusion into a product mold constitute the first step in the extrusion blow molding production process. Air is pushed in to inflate the parison against the mold walls as the mold closes around it.

The mold opens and the part is evacuated once the plastic has returned to a solid state. Deflashing, a technique that removes surplus material along the mold pinch line, is the last step before the item is prepared for any additional operations required to complete it.

To preserve ID and OD specifications and add features to the product, extrusion blow molding is frequently combined with compression molding and insert molding:

Ø Plastic compression molding

The exterior diameter (OD) of a part can typically be tightly controlled with extrusion blow molding plastic, but the inside diameter tolerances cannot always be precisely controlled (ID). We can accurately regulate the OD and ID of your product by combining the blow molding and plastic compression molding processes.

Ø Plastic insert molding

Fasteners and/or other inserts can be included right inside the mold when blow molding plastic and incorporating plastic insert molding. By doing so, the production process is simplified and a stronger link between the blow-molded and insert-molded components is created. Riveting and welding are two stages that would otherwise add time to the process without adding any value.

Is Blow Molding an Appropriate Choice for Me?

When the annual production volume of more than 3,000 parts hits a certain threshold, blow molding emerges as the most efficient and time-saving method of plastic molding.

It should come as no surprise that engineers working in practically every sector of the economy throughout the world are looking to blow molding as a solution to meet their high-production requirements, given the growing emphasis on lightweighting and sustainability.

The following are some of its many advantages:

Ø Blow molding is more cost-efficient than other methods such as roto-molding and thermoforming for mass-produced hollow parts. This is due to blow molding's ability to create a huge volume of parts at a cheap cost.

Ø A high strength-to-weight ratio is achieved by reinforcing individual parts with a lightweight foam core or internal ribs to boost the structural strength and impact resistance of the finished product.

Ø Flexibility in design - It is possible to obtain intricate part geometries to accommodate odd spaces between already existing components.

Ø Insulation and acoustical properties - Hollows can either be sucked out or filled with a material to produce high insulation and noise reduction capabilities.

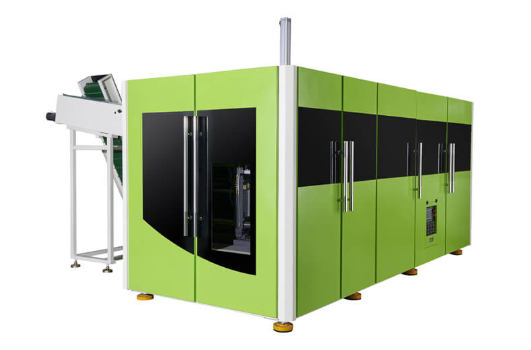

Contact Us for Your Blow Molding Machine

The formation of hollow plastic objects, such as water bottles and juice bottles, can be accomplished by an engineering process known as blow molding.

Contact us if you're interested in buying a blow molding machine or learning more about this or any other blow molding method.